Lathe

1 Introduction

Lathe is considered as one of the oldest

machine tools and is widely used in industries. It is called as mother of

machine tools. The first screw cutting lathe was developed by an Englishman

named Henry Maudlay in the year 1797. Modern high speed, heavy duty lathes

are developed based on this machine.

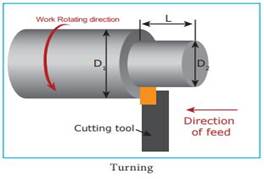

2 Turning

The

primary task of a lathe is to generate cylindrical work pieces. The process of

machining a work piece to the required shape and size by moving the cutting

tool either parallel or perpendicular to the axis of rotation of the work piece

is known as turning.

In this process, excess unwanted

metal is removed. The machine tool useful in performing plain turning, taper

turning, thread cutting, chamfering and knurling by adopting the above method

is known as lathe.

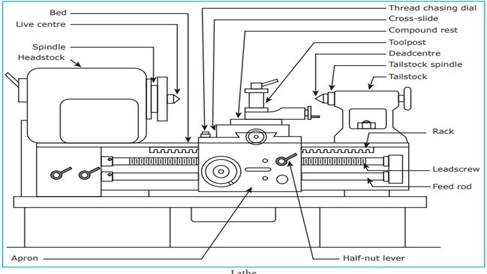

3 Structure of Lathe

The lathe has bed

on which head stock is mounted on left end, tailstock at right end and carriage

is placed and moved on the bed.

4 Main parts of a lathe

Every individual part performs an important task in a lathe.

Some important parts of a lathe are listed below.

1.

Bed

2.

Headstock

3.

Spindle

4.

Tailstock

5.

Carriage

a.

Saddle

b.

Cross slide

c.

Compound rest

d.

Compound slide

e.

Tool post

f. Apron

6.

Lead screw

7.

Feed rod

Bed

Bed is mounted on the legs of the lathe which are

bolted to the floor. It forms the base of the machine. It is made of cast iron

and its top surface is machined accurately and precisely. Headstock of the

lathe is located at the extreme left of the bed and the tailstock at the right

extreme. Carriage is placed in between the headstock and tailstock moves on the

bed guide ways.

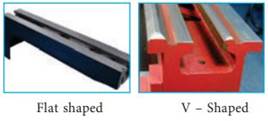

The top of the bed has a guide ways which is

manufactured in two shapes

1. Flat shaped

2. V Shaped

The tailstock and

the carriage slides on these guide ways. Flatbed guide ways can be found in

older machine tools. It is useful in heavy duty machines, handling large work

pieces. Though, it is less accuracy. V-type bed have been found in modern

machine tools. This type of V-bed gives accurate alignment to carriage and

tailstock. The metal chips automatically fall through.

Headstock

Headstock is mounted permanently on the inner

guide ways at the left hand side of the lathe bed. The headstock houses a

hollow spindle and the mechanism for driving the spindle at multiple speeds.

The headstock will have any of the following arrangements for driving and

altering the spindle speeds.

1. Stepped cone pulley mechanism

2. Back gear mechanism

3. Gear box mechanism

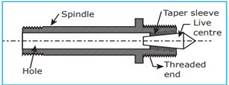

Spindle

The spindle freely

rotates on two large bearings housed on the headstock casting. It is made of

carbon or nickel chrome steel. A hole extends through the spindle so that a

long bar stock may be passed through the hold. The front end of the spindle is

threaded on which any one of the work holding devices can be screwed. The front

end of the hole is tapered to receive live centre which supports the work. On

the other side of the spindle, a gear known as a spindle gear is fitted.

Through this gear, tumbler gears and a main gear train, the power is

transmitted to the gear on the lead screw.

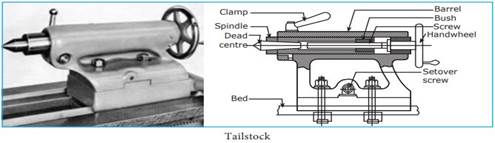

Tailstock

Tailstock is

located on the inner guide ways at the right side of the lathe bed. The body of

the tailstock is bored and houses the tailstock spindle. The spindle moves

front and back inside the hole. The spindle has a tapper hole to receive the

dead centre or shanks of tool like drill or reamer. If the tailstock hand wheel

is rotated in clockwise direction, the spindle advances. The spindle will be

reversed inside the hold, if the handwheel is rotated

in anti-clockwise direction.

To

remove the dead centre or any other tool from the spindle, the hand wheel is

rotated in anticlockwise direction further. The movement of the spindle may be

locked by spindle clamp, located on top of the tailstock. To hold different

lengths of work, the tailstock can be adjusted and locked at desired position

on the lathe bed. The casting of the tailstock body is divided into two. The

lower casting of the body can be clamped to the bed. The upper casting can be

moved side wards from lathe axis.

Uses of Tailstock

1.

It supports the right end of the long work piece

when it is machined between centres.

2.

It is useful in holding tools like drills, reamers

and taps when performing drilling, reaming and tapping.

3.

The upper casting of the body is set off by a

small distance from the axis of the lathe to turn tapers on the work pieces.

4.

It is useful in setting the cutting tool at

correct height aligning the cutting edge with lathe axis.

Carriage

Carriage

is located between the headstock and tailstock on the lathe bed guideways. It

can be moved along the bed either towards or away from the headstock. It has

several parts to support, move and control the cutting tool.

The parts

of the carriage are

a. Saddle

b. Cross slide

c.

Compound rest

d. Compound slide

e. Tool post

f.

Apron

Saddle

Saddle connects the

front and back portion of bed guide ways like a bridge. It is an H shaped

casting. It moves along the bed between headstock and tailstock. The saddle can

be moved by providing hand feed or automatic feed.

Cross slide

Cross slide is situated on the saddle and

slides on the dovetail guideways at right angles to the bed guideways. It

carries compound rest, compound slide and tool post. The cross slide can be

moved at right angles to the lathe axis by giving hand feed or automatic feed.

Compound rest

Compound

rest is a part which connects cross slide and compound slide. It is mounted on

the top of the cross slide by tongue and groove joint. It has a circular base

on which angular graduations are marked. The compound rest can be swivelled to

the required angle while turning tapers. A top slide known as compound slide is

attached to the compound rest by dove tail joint. The tool post is fixed on the

compound slide.

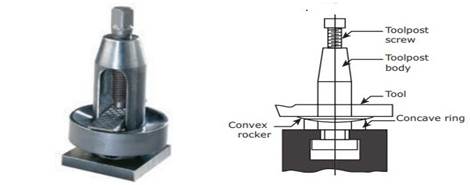

Tool post

The tool post is mounted on the compound

slide. It is used for holding the cutting tool tightly. According to the

operations on the work piece, tool may be changed and fixed on the tool post.

There are different types of tool post. In which,

1. Single screw tool post

2. Four way tool post are widely used.

Single screw tool post

One tool can be held by the single screw tool

post. The tool is clamped by one clamping screw. A concave ring is found in the

tool post. A convex rocker iron piece has got a convex surface at its bottom

and flat surface at its top. This rocker iron piece is placed on the concave

ring. The tool rests on the top flat surface of the rocker.

The height of the tool point can be adjusted

by moving the rocker front and back. As the tool is clamped by only one

clamping screw, it is not preferable for heavy duty works.

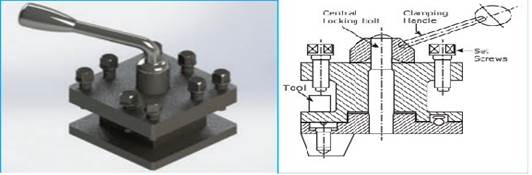

Four way tool post

Four way tool post is known as Turret tool

post. Four different types of tool can be placed and clamped at a time. The

required tool can be turned towards the work piece for turning

Process.

As the required tools fitted ready in position, the turning work is easier and

faster. This type of tool post is used in heavy duty lathes.

5 Feed Mechanism

By using various

feed mechanism, the rotation of lead screw and feed rod direction can be

changed and so the direction of carriage and cross slide movements can also be

changed. There are so many feed mechanisms used in lathe, among them the

important mechanisms are discussed below.

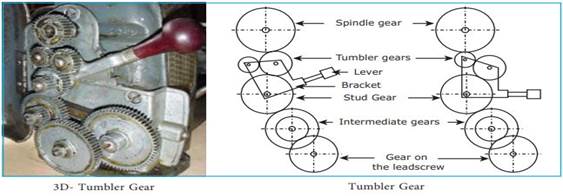

6 Tumbler Gear

A set of two small

gears are placed just below the spindle gear and connected to the spindle gear

in the lathe. The set of gears is known as tumbler gear. The set of two small

tumbler gears are fitted in a bracket. The bracket position can be adjusted

into three positions such as neutral, upwards and downwards. By adjusting the

position of tumbler gear, the rotation of lead screw and feed rods direction

can be changed.

Neutral Position

In this position,

the tumbler gears lever is in the middle position hence, the tumbler gears are

not engaged with spindle gear and the intermediate gears and so, automatic feed

is not received.

Forward position

In this position,

the tumbler gears lever is shifted upward position. Here only one tumbler gear

is in contact with the spindle gear, hence, the lead screw rotates in the same

direction of the spindle rotation. The carriage moves towards headstock.

Reverse Position

In this position,

the tumbler gears lever is pushed downward position. Here leadscrew and feed

rod receive rotational movement from spindle gear through tumbler gears. Hence,

they rotate in opposite direction of the spindle rotation. So the carriage will

move towards tailstock.

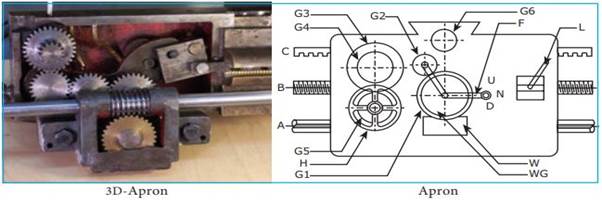

7 Apron Mechanism

Apron is attached

to the carriage and hangs over the front side of the lathe bed. It is useful in

providing power and hand feed to both carriage and cross-slide. It is also used

to provide power feed to the carriage during thread cutting through two half

nuts.

The

gear attached to the spindle is called spindle gear. Feed rod (A) and lead

screw (B) receives rotational movement from spindle gear through the tumbler

gear. Worm (W) and worm gear (WG) mechanism is fixed in worm gear rod (A). One

more gear (G) is fixed in worm gear shaft. Gear G1 and G2

is connected as shown in the figure. Gear G4 is inserted in the rack

gear. Gear G3 is mounted on Gear G4 axis. Handle (H) for

longitudinal feed and gear G5 are mounted on the same axis. Gears G3

and G5 are always connected each other. There is a feed check lever

(F), which can be adjusted into three positions such as neutral, upwards and

downwards so, the following movements can be obtained.

Hand feed to the carriage

Keep the feed check

lever (F) in neutral position and if cross feed wheel is rotated by hand, the

cross slide moves towards the lathe axis.

Automatic feed to the cross slide

When feed check

lever is kept in downward (D), gear G2 will be connected to G6. The rotation of

G6 will make the cross slide to move automatically.

Automatic feed to the carriage for thread cutting

When the two half

nuts in the apron are connected to the leadscrew by using lever (L), leadscrew

makes the carriage to move automatically and cut threads for required pitch

value.

Lead screw

The lead screw is a

long threaded shaft. It is used for moving the carriage automatically to a

calculated distance only when threads have to be cut. Mostly lead screws have

an acme thread.

The leadscrew is

held between two bearing infront of the lathe bed. A gear is attached to the

leadscrew at left end. The gear is called as gear on leadscrews. A half nuts

lever is provided in the apron to engage the halfnuts with the leadscrew.

If the half nuts

are engaged with the running screw the carriage will move automatically. When

the lead screw is kept stationary the carriage is locked at the required

position by using half nuts.

Feed Rod

Feed

rod is placed parallel to the leadscrew infront side of the bed. It is a plain

long shaft which has a keyway along its length. The power is transmitted from

the spindle to the feed rod through tumbler gears and a gear train. It is

useful for providing feed movement to the carriage and cross slide, except

thread cutting time.

8 Spindle Mechanism

The spindle is

located in the headstock and it receives the driving power from the motor. The

spindle speed should be changed to suit different machining conditions like

type of material to be cut, the diameter and the length of the work, type of

operation, the type of cutting tool material used, the type of finish desired

and the capacity of the machine. In order to change the spindle speeds, any one

of the following methods are employed.

1. Stepped

cone pulley mechanism

2. Back gear

mechanism

3. Gear box

mechanism

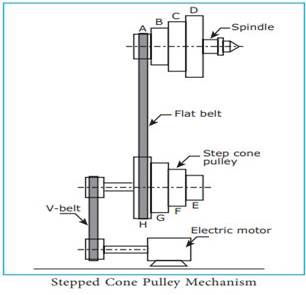

9 Stepped Cone Pulley Mechanism

It

is simple in construction. A stepped cone pulley is attached with the spindle

contained within the headstock casting. The cone pulley has four steps (A, B, C

& D). Another cone pulley having four steps (E, F, G and H) is placed

parallel to the spindle cone pulley. Both the cone pulleys are connected by a

flat belt. The belt can be arranged between the steps A & H, B & G, C

& F and D & E. The cone pulley at the bottom is connected to the

electric motor by a V belt. So the cone pulley at the bottom rotates at a

particular speed.

The belt is arranged on any one

of the four steps to obtain different spindle speeds. If the belt is placed on

the smaller step of the driven pulley, the spindle speed will be increased. For

example, when the belt is arranged between A & H the spindle speed will be maximum.

When it is between D & E, the speed will be minimum. Stepped cone pulley

drive is illustrated in figure.

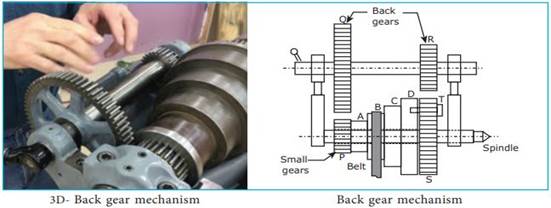

10 Back gear mechanism

Back gear mechanism is housed within the

headstock of the lathe. A step cone pulley having steps ABCD and a small pinion

P are mounted on the spindle and rotates freely on it. The gear S is keyed

to the head stock spindle. So the spindle will rotate only when the gear s rotates.

The

step cone pulley ABCD and the gear S can be kept separately or made as one

unit with the help of a pin T when the pin is disengaged, the cone pulley

along with the gear P will rotates freely on the spindle and the spindle will

not rotate. There is another shaft parallel to the spindle axis having back

gear Q and R mounted on it. These back gears can be made to mesh with gears P

and S or kept disengaged from them. The spindle can get drive either from the

cone pulley or through back gears.

Drive from step cone pulley

When the spindle

gets from the cone pulley, the back gears Q and R are

disengaged from the gears P and S. The pin T is engaged with cone pulley. The

belt can be arranged on the steps ABC or D to get four different direct speeds

for the spindle.

Drive through back gears

Back

gears Q and R are engaged with gears P and S. The pin T is disengaged from

the cone pulley to make the cone pulley and the spindle separate units. When

the cone pulley gets drive through the belt, the power is transmitted through

the gears P, Q and R to the gear S, because of number of teeth on these gears,

the spindle rotates at slower speeds. By arranging the belt on the different

steps of the cone pulley, four different spindle speeds are obtained.

Uses of back gear arrangement

1. It is

used for reducing the spindle speed, when turning on lager diameter of the work

pieces and cutting coarse threads.

2. Eight

different types of spindle speed can be obtained by this mechanism.

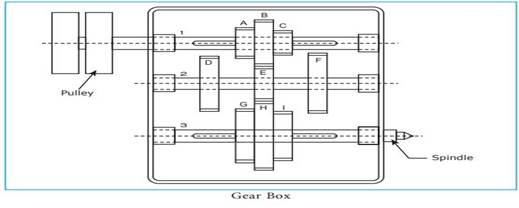

11 Gear Box Mechanism

Modern lathes are equipped with

all geared headstocks to obtain different spindle speeds quickly. Casting of

the all geared headstock has three shafts (1, 2 & 3) mounted within it. The

intermediate shaft (2) has got three gears D, E and F and rotates at the same

place and cannot move. The shaft (1) which is above the intermediate shaft has

got three set of gears A, B and C mounted on it by keys. These three set of

gears can be made to slide on the shaft with the help of a lever. This movement

enables the gear A to have contact with the gear D or the gear B with gear E or

the gear C with the gear F.

Likewise

the spindle shaft (3) which is also splined has three set of gears G, H and I.

These three set of gears can be made to slide on the shaft by lever. This

sliding movement enables the gear G to have contact with gear D or the gear H

with the gear E or the gear I with the gear F. By altering the position of the

six gears namely A, B, C, G, H and I the following arrangements can be made

within the headstock. Nice different spindle within the headstock. Nine

different spindle speeds are obtained.

12 Types of lathe

Various designs and

constructions of lathe have been developed to suit different machining

conditions and usage. The following are the different types of lathe.

1. Speed

lathe

a. Cantering lathe

b. Wood working lathe

c. Polishing lathe

d. Metal spinning lathe

2. Bench

lathe

3. Tool room

lathe

4. Semi-Automatic

lathe

a. Capstan lathe

b. Turret lathe

5. Automatic

lathe

6. Special

purpose lathe

a. Wheel lathe

b. Gap bed lathe

c. T lathe

d. Duplicating lathe

Speed lathe

Spindle of a speed lathe operates

at very high speeds (approximately at a range of 1200 to 3600 rpm) and so it is

named so. It consists of a headstock, a tailstock, a

bed and tool slide only. Parts like leadscrew, feed rod and apron are not found

in this type of lathe.

1. Centering

lathes are used drilling centre holes.

2. The wood

working lathes are meant for working on wooden planks.

3. Metal

spinning lathes are useful in making tumblers and vessels from sheet

metal.

4. Polishing

of vessels is carried out in polishing lathe.

Bench lathe

Bench lathe is a small lathe

generally mounted on a bench. It consists of all the parts of an engine lathe.

It is used for small works like machining tiny and precise parts and parts of

measuring instruments.

Tool room lathe

A tool room lathe has similar features of an engine lathe but

is accurately built and has wide range of spindle speeds to perform precise

operations and different feeds. It is costlier than a centre lathe. This is

mainly used for precision works like manufacturing tools, dies, jigs, fixtures

and gauges.

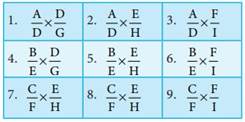

Semi-Automatic lathe

Turret

and capstan lathes are known as semi-automatic lathes. These lathes are used

for production work where large quantities of identical work pieces are

manufactured. They are called semiautomatic lathes as some of the tasks are

performed by the operators and the rest by the machines themselves.

There

are two way tool posts in the machine namely four way tool post and rear tool

post. Four tools can be mounted on the four way post and parting tool is

mounted on the rear tool post. The tailstock of an engine lathe is replaced by

a hexagonal turret. As many tools may be fitted on the size side of the turret,

different types of operations can be performed on a work piece without

resetting of tools.

Advantages

1. Machining

operations can be done in this machine by semi-skilled operators.

2. Large

quantity of product can be produced quickly.

3. The cost

of production is less.

Automatic lathe

Automatic

lathes are operated with complete automatic control. They are high speed, mass

production lathe. An operator can took after more than are automatic lathe at a

time.

Special purpose lathe

Special

purpose lathes are used for special purposes and for jobs, which cannot be

accommodated and conveniently machined on a standard lathe. Wheel lathe, T

lathe duplicating lathe are some examples of special purpose lathe.

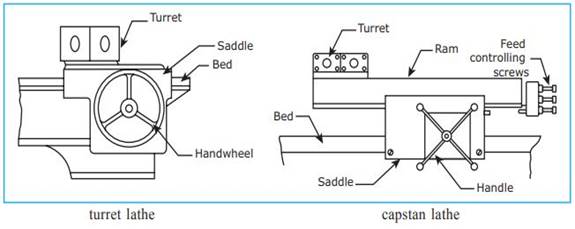

13

Differences between a turret lathe and a capstan lathe

14 Specification of lathe

The size of a lathe is specified by the following points

1. The

length of the bed.

2. Maximum

distance between live and dead centres.

3. The

height of centres from the bed.

4. The swing

diameter

a.

The swing diameter over bed

It

refers to the largest diameter of the work that will be rotated without

touching the bed.

b.

The swing diameter over carriage

It

refers to the largest diameter of the work that will revolve over the saddle.

5. The bore

diameter of the spindle.

6. The width

of the bed.

7. The type

of the bed.

8. Pitch

value of the lead screw.

9. Horse power of the motor.

10.

Number and range of spindle speeds.

11. Number of

feeds.

12. Spindle

nose diameter.

13. Floor

space required.

14. The type

of the machine.

15 Work Holding Devices used in a lathe

The work holding

devices are used to hold and rotate the work pieces along with the spindle.

Different work holding devices are used according to the shape, length,

diameter and weight of the work piece and the location of turning on the work.

They are,

1. Chucks

2. Face

plate

3. Driving

plate

4. Catch

Plate

5. Carriers

6. Mandrels

7. Centres

8. Rests

Chucks

Work

pieces of short length, large diameter and irregular shapes, which cannot be

mounted between centres, are held quickly and rigidly in chuck. There are

different types of chucks namely, three jaw universal chuck, four jaw

independent chuck, Magnetic chuck, Collect chuck and Combination chuck.

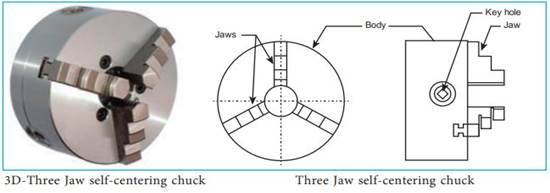

Three Jaw self-cantering chuck

The three jaws

fitted in the three slots may be made to slide at the same time by an equal amount

by rotating any one of the three pinions by a chuck key. This type of chuck is

suitable for holding and rotating regular shaped work pieces like round or

hexagonal rods about the axis of the lathe.

Advantages

1. The work

is held simply and quickly because of the three jaws are moved to slide at the

same time.

2. So, time

is saved.

3. It is

suitable for apprentice.

Disadvantage

1.

Work pieces of irregular shapes cannot be held by

this chuck.

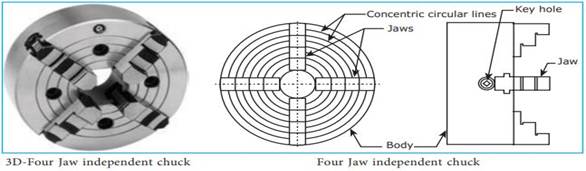

Four jaw independent chuck

There are four jaws in this

chuck. Each jaw is move independently by rotating a screw with the help of a

chuck key. A particular jaw may be moved according to the shape of the work.

Hence this type of chuck can hold works of irregular shapes. Concentric circles

are inscribed on the face of the chuck to enable quick cantering of the work

piece.

Disadvantages

1. It

requires more time to set the work aligned with the lathe axis because each jaw

is moved independently.

2. Experienced

turners can set the work about the axis quickly.

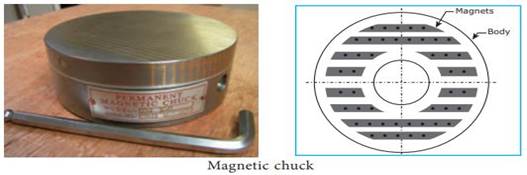

Magnetic chuck

The holding power of this chuck

is obtained by the magnetic flux radiating from the electromagnet placed inside

the chuck. Magnets are adjusted inside the chuck to hold or release the work.

Work piece made of magnetic material only are held in this chuck. Very small,

thin and light works which cannot be held in an ordinary chuck are held in this

chuck.

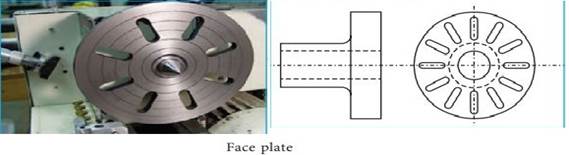

Face plate

Face plate is used to hold large,

heavy and irregular shaped work pieces which cannot be conveniently held

between centres. It is circular disc bored out and threaded to fit to the nose

of the lathe spindle. It is provided with radial plain and T slots for

holding the work by bolts and clamps.

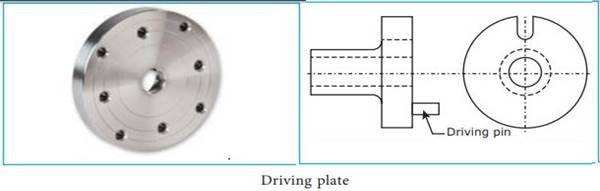

Driving plate

The

driving plate is used to drive a work piece when it is held between centres. It

is a circular disc screwed to the nose of the lathe spindle. It is provided

with small bolts or pins on its face. Work pieces fitted inside straight tail

carriers are held and rotated by driving plates.

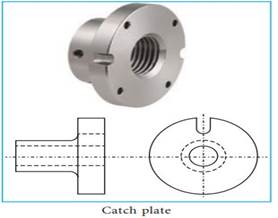

Catch plate

When

a work piece is held between centres, the catch plate is used to drive it. It

is a circular disc bored and threaded at the centre. Catch plates are designed

with U- slots or elliptical slots to receive the bent tail of the carrier.

Positive drive between the lathe spindle and the workpiece

is affected when the work piece fitted with the carrier fits into the slot of

the catch plate.

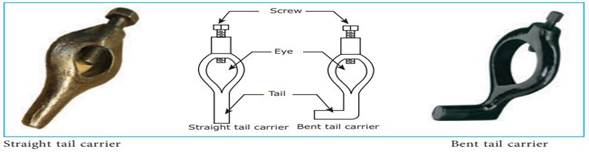

Carrier

When a work piece is held and

machined between centrers, carriers are useful in

transmitting the driving force of the spindle to the work by means of driving

plates and catch plates. The work is held inside the eye of the carrier and

tightened by a screw. Carriers are of two types and they are:

1.

Straight tail carrier

2. Bent tail

carrier

Straight tail

carrier is used to drive the work by means of the pin provided in the driving

plate. The tail of he bent tail carrier fits into the slot of the catch plate

to drive the work.

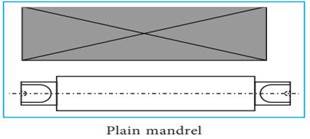

Mandrel

A

previously drilled (or) bored work piece is held on mandrel to be driven in a

lathe and machined. There are centre holes provided on both faces of the

mandrel. The live centre and the dead centre fit into the centre holes. A

carrier is attached at the left side of the mandrel. The mandrel gets the drive

either through a catch plate or a driving plate. The work piece rotates along

with the mandrel. There are several types of mandrels and they are:

1. Plain

mandrel

2. Step

mandrel

3. Gang

mandrel

4. Screwed

mandrel

5. Collar

mandrel

6. Cone

mandrel

7. Expansion

mandrel

Plain mandrel

The body of the plain mandrel is slightly

tapered to provide proper gripping of the work piece. The taper will be around

1 to 2 mm for a length of 100 mm. It is also known as solid mandrel. This type

is mostly commonly used and has wide application.

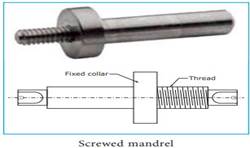

Screwed mandrel

It is

threaded at one end and a collar is attached to it. Work pieces having internal

threads are screwed on to it against the collar for machining.

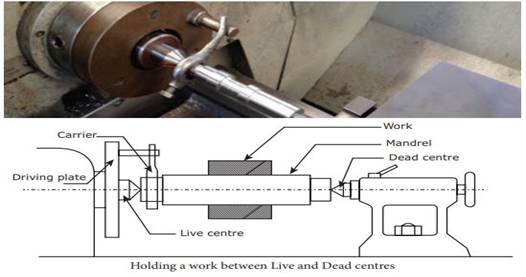

Centres

Centres are useful in holding the work in a

lathe between centres. The shank of a centre has morse taper on it and the face is conical in shape.

There are two types of centres namely

1.

Live centre

2.

Dead centre

Live centre

The live centre is fitted on the headstock spindle

and rotates with the work.

Dead centre

The centre fitted

on the tailstock spindle is called dead centre. It is useful in supporting the

other end of the work. Centres are made of high carbon steel and hardened and

then tempered. So the tips of the centres are wear resistant. Different types

of centres are available according to the shape of the work and the operation

to be performed.

Holding a

work between Live and Dead centres

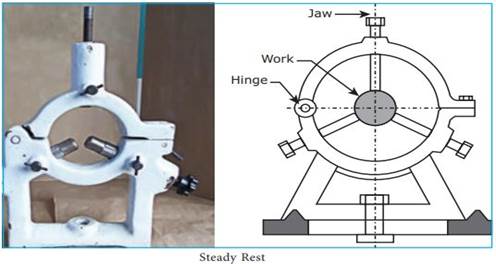

Rests

A rest is a mechanical device to support a

long slender work piece when it is turned between centres or by a chuck. It is

placed at some intermediate point to prevent the work piece from bending due to

its own weight and vibrations setup due to the cutting force. There are two

types of rests

1.

Steady rest

2.

Follower rest

Steady rest

Steady

rest is made of cast iron. It may be made to slide on the lathe bed ways and

clamped at any desired position where the work piece need support. It has three

jaws. These jaws can be adjusted according to the diameter of the work.

Machining is done upon the distance starting from the headstock to the point of

support of the rest. One or more steady rests may be used to support the free

and of a long work.

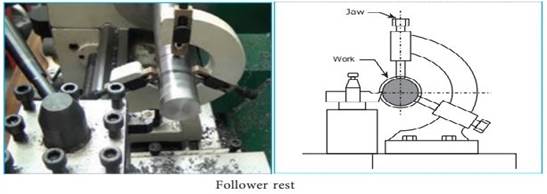

Follower rest

It consists

of a C like casting having two adjustable jaws to support the work piece. The

rest is bolted to the back end of the carriage. During machining, it supports

the work and moves with the carriage. So, it follows the tool to give

continuous support to the work to be able to machine along the entire length of

the work.

16 Cutting speed, Feed and Depth of cut in lathe

The cutting speed

is the distance travelled by a point on the outer surface of the work is one

minute.

It is expressed in

meters per minute.

Cutting speed = ![]() m/min

m/min

Where, D is the

diameter of the work in mm

N is

the r.p.m of the work.

Feed

The feed of a

cutting tool in a lathe work is the distance the tool advance for each

revolution of the work.

Feed is expressed in millimetres per revolution.

Depth of cut

The depth of cut is

the perpendicular distance measured from the machined surface to the uncut

surface of the work piece. It is expressed in millimeters.

In a lathe, the depth

of cut is expressed as follows

Depth of cut = d1

-d 2 /2 ,

Where,

d1 diameter of the work surface before

machining

d2 diameter of the machined surface

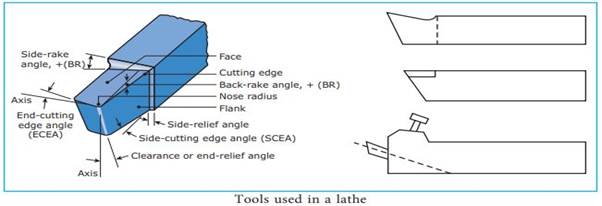

17 Tools used in a lathe

Tools used in lathe are classified as follows

A. According to the construction, the lathe tools are

classified into three types

1. Solid

tool

2. Brazed

tipped tool

3. Tool bit

and tool holders

B. According to the operation to be performed, the cutting

tools are classified as

1. Turning

tool

2. Thread

cutting tool

3. Facing

tool

4. Forming tool

5. Parting tool

6. Grooving tool

7. Boring tool

8. Internal thread cutting tool

9. Knurling tool

C. According to the direction of feed movement, the following

tools are used

1. Right

hand tool

2. Left hand

tool

3. Round

nose tool

18 Operations performed in lathe

Various operations are performed in a lathe other than plain

turning.

There are

1.

Facing

2.

Turning

a. Straight

turning

b. Step

turning

3.

Chamfering

4.

Grooving

5.

Forming

6.

Knurling

7.

Under cutting

8.

Taper

turning

9.

Thread

cutting

Other works are done in lathe

1. Drilling

2. Reaming

3. Boring

4. Grinding

5. Milling

6. Key ways

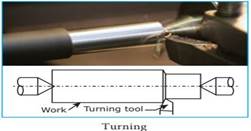

Turning

The work is turned

straight when it is made to rotate about the lathe axis. The purpose of turning

is to produce a cylindrical surface by removing excess metal from the work

piece.

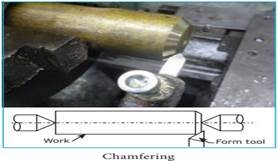

Chamfering

Chamfering is the

operation of bevelling the extreme end of the work piece. The form tool used

for taper turning may be used for this purpose. Chamfering is an essential

operation after thread cutting so that the nut may pass freely on the threaded

work piece.

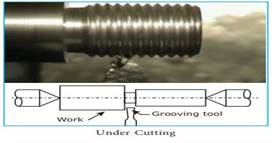

Undercutting

Undercutting is done

1. At the

end of a hole

2. Near the

shoulder of stepped cylindrical surfaces

3. At the

end of the threaded portion in bolts

It

is a process of enlarging the diameter if done internally and reducing the

diameter if done externally over a short length. It is useful mainly to make

fits perfect. Boring tools and parting tools are used for this operation.

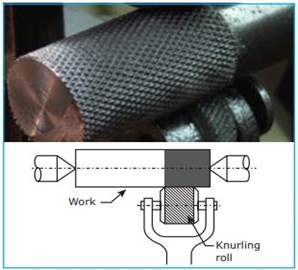

Knurling

Knurling

is the process of embossing a diamond shaped pattern on the surface of the work

piece. The knurling tool holder has one or two hardened steel rollers with

edges of required pattern. The tool holder is pressed against the rotating

work. The rollers emboss the required pattern. The tool holder is fed

automatically to the required length. Knurls are available in coarse, medium

and fine pitches. The patterns may be straight, inclined or diamond shaped.

The purpose of knurling is

1. To provide an effective gripping surface.

2. To provide better appearance to the work.

3. To slightly increase the diameter of the work.

19 Taper turning

Taper

A taper may be

defined as a uniform increase or decrease in diameter of a piece of work

measured along its length.

Taper turning method

1. Form tool

method

2. Compound

rest method

3. Tailstock

set over method

4. Taper

turning attachment method

5. Combined

feed method

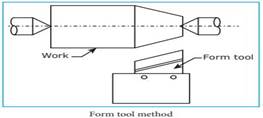

Form tool method

A

broad nose tool is ground to the required length and angle. It is set on the

work by providing feed to the cross slide. When the tool is fed into the work

at right angles to the lathe axis, a tapered surface is generated.

This

method is limited to turn short lengths of taper only. The length of the taper

is shorter than the length of the cutting edge. Less feed is given as the

entire cutting edge will be in contact with the work.

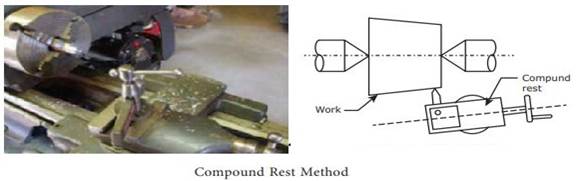

Compound Rest Method

The

compound rest of the lathe is attached to the circular base graduated in

degrees, which may be swiveled and clamped at any desired angle. The angle of

taper is calculated using the formula.

![]()

Where,

D Larger diameter

d

Small diameter

l

Length of the taper

The compound is swiveled to the angle as above and clamped.

Feed is given to the compound slide to generate the required taper.

Advantage

Taper turning can

be done on outer surface of the work piece and inner surface of the hole.

Disadvantage

1. This

method is not suitable for long work piece, because compound slide moves only

small distance.

2. This method

is done manually so, it takes more time and the productivity is less.

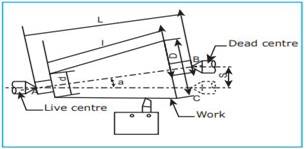

Tailstock set over method

Turning

taper by the set over method is done by shifting the axis of rotation of the

work piece at an angle to the lathe axis and feeding the tool parallel to the

lathe axis. The construction of tailstock is designed to have two parts namely

the base and the body. The base is fitted on the bed guide ways and the body

having the dead centre can be moved at cross to shift the lathe axis.

The amount of set over-S, can be calculated as follows

![]()

Where, S Amount of set over

D Larger diameter

d Smaller

diameter

L Length of the

work

l Length of the

taper

The dead centre is suitably

shifted from its original position to the calculated distance. The work is held

between centres and longitudinal feed is given by the carriage to generate the

taper.

Advantages

1. Taper

turning can be done to full length of the work piece.

2.

Taper thread cutting can also be cut in this

method.

Disadvantages

1. This type

of taper turning can be done up to angle of 80.

2. Internal taper turning cannot be done by this

method.

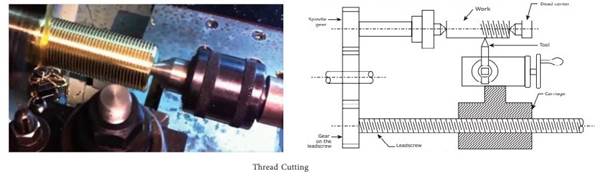

20 Thread Cutting

Thread

cutting is one of the most important operations performed in a lathe. The

process of thread cutting is to produce a helical groove on a cylindrical

surface by feeding the tool longitudinally.

1. The job

is revolved between centres or by a chuck. The longitudinal feed should be

equal to the pitch of the thread to be cut per revolution of the work piece.

2. The

carriage should be moved longitudinally obtained feed through the leadscrew of

the lathe.

3. A

definite ratio between the longitudinal feed and rotation of the head stock

spindle should be found out. Suitable gears with required number of teeth

should be mounted on the spindle and the leadscrew.

Calculation

for change gear

![]()

By using the above

formula, calculate the thread to be cut and connect the gear on the spindle and the gear on leadscrew.

4.

A proper thread cutting tool is selected according

to the shape of the thread. It is mounted on the toolpost

with its cutting edge at the lathe axis and perpendicular to the axis of the

work.

5. The

position of the tumbler gears are adjusted according to the type of the thread

(right hand or left hand).

6. Suitable

spindle speed is selected and it is obtained through back gears.

7. Half nut

lever is engaged at the right point as indicated by the thread chasing dial.

8. Depth of

cut is set suitably to allow the tool to make a light cut on the work.

9. When the cut is made for required length, the

half nut lever is disengaged. The carriage is brought back to its original

position and the above procedure is repeated until the required depth of the

thread is achieved.

10.

After the process of thread cutting is over, the

thread is checked by suitable gauges.