Milling Machine

1 Introduction

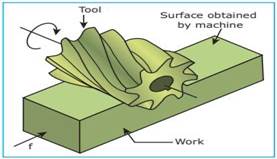

Milling is a process of removing

metal by feeding the work against a rotating multipoint cutter. The machine

tool intended for this purpose is known as milling machine.

It is found in shops where tools

and cutters are manufactured. The surface obtained by this machine tool is

superior in quality and more accurate and precise.

Advantages

1.

The metal is removed at a faster rate as the

cutter has got multiple cutting edges and rotates at a higher speed.

2.

It is possible to perform machining by mounting

more than one cutter at a time.

3.

The able of the machine can be moved to an

accuracy of 0.02 mm.

4.

It is very useful since various cutters and

precise tools can be machined.

5.

Special attachments can be mounted on the machine to

perform operations that are performed in other machine tools.

Disadvantages

1.

The cost of the milling machine is high.

2.

As milling cutters cost high, the investment for

procuring tools is more.

3.

The production cost will increase if we carry out

the operations performed in a shaper or a drilling machine with a milling

machine.

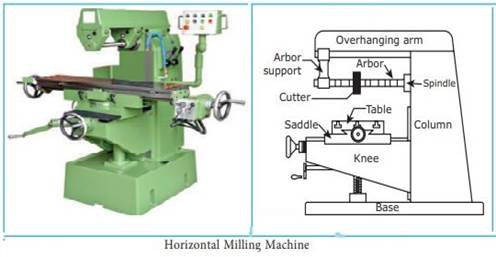

2 Horizontal Milling Machine

Base

It is made of cast iron and

supports all the other parts of the machine tool. A vertical column is mounted

upon the base. In some machines, the base serves as a reservoir for cutting

fluid.

Column

It is mounted upon the base and

it is box shaped. It houses the mechanism for providing drive for the spindle.

The front vertical face of the

column is machined accurately to form dovetail guideways for the knee to move

up and down. The top of the column holds an overhanging arm.

Knee

It slides up and down on the

guideways of the column. An elevating screw mounted on the base obtains this

movement. Saddle is mounted upon the knee and moves in a crosswise direction.

Saddle

It is mounted on the guideways of

the knee and moves towards or away from the face of the column. This movement

can be obtained either by power or by hand. The top of the saddle has guideways

for the table movement.

Table

The table is moved longitudinally

either by power or manually on the guideways of the saddle. The trip dogs,

placed on it, control the movement of the table.

The table of a universal milling

machine can be swiveled horizontally to perform helical works. The top surface

of the table has got T slots on which the workpieces or other work holding

devices are mounted.

Spindle

It is located in the upper part

of the column. It receives power from the motor through belt, gears and

clutches. The front end of the spindle has got a taper hole into which the

cutters are held with different cutter holding devices.

Over arm

It supports the arbor from the top of the column. The arbor

is supported by the bearing fitted within the arbor

support. It is also useful while using some special attachments.

Arbor

It supports the different types

of cutters used in the machine. It is drawn into the taper hole of the spindle

by a draw bolt.

One or more cutters are mounted

on the arbor by placing spacing collars between them.

The

arbor is supported by an arbor

support. The arbor is provided with a morse taper or self-releasing

taper.

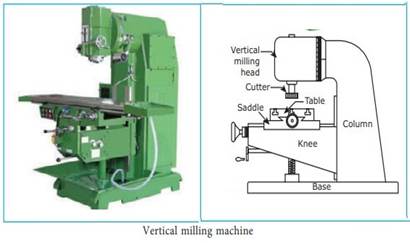

3 Vertical milling machine

It is very similar to a

horizontal milling machine in construction as it has the same parts of base,

column, knee, saddle and table. The spindle of the machine is positioned

vertically. The cutters are mounted on the spindle is rotated by the power

obtained from the mechanism placed inside the column. Angular surfaces are

machined by swiveling the spindle head.

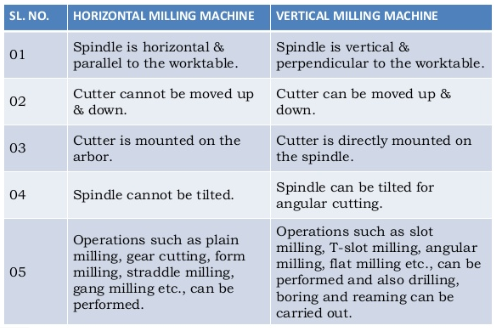

Differences

between Horizontal and vertical milling machine

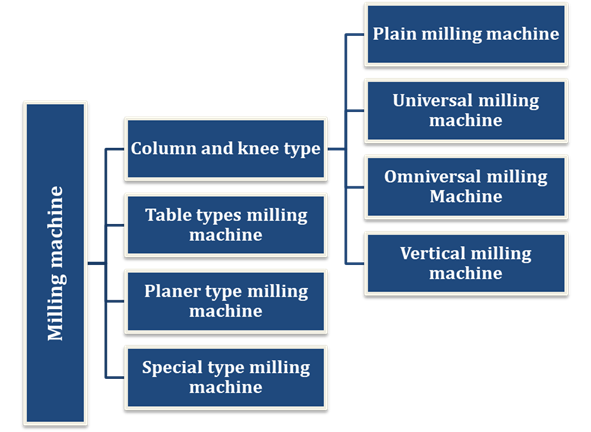

4 Types of milling machine

The milling machines are classified according to

the general deign of the machine.

1.

Column and knee type

a. Plain milling machine

b. Universal milling machine

c. Omniversal milling

Machine

d. Vertical milling machine

2.

Table types milling machine

3.

Planer type milling machine

4.

Special type milling machine

Column and knee type milling machine

The column of a column and knee

type milling machine is mounted vertically upon the base. Knee is mounted on

the accurately machined guideways of the column. It is designed to move up and

down accurately. Saddle and table are mounted on the knee.

There are different types of column and knee type

machines.

a. Plain

milling machine

It is rigid and sturdy. Heavy

workpieces are mounted and machined on the machine. The work mounted on the

table is moved vertically, longitudinally and crosswise against the rotating

cutter. The table cannot be rotated. It is also called as horizontal milling

machine because the cutter rotates in horizontal plane.

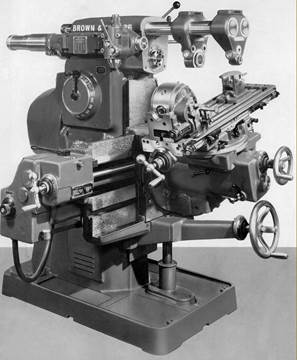

b. Universal

milling machine

The table of a universal milling

machine can be swiveled by 450 on either side and so helical milling works can

be performed. It is named so because it can be adapted for a very wide range of

milling operations. Various milling attachments like index head, vertical

milling head, slot milling head and rotary table can be mounted. It can be

machine drills reamers, gears, milling cutters with a very high degree of

accuracy and so it finds an important place in workshop.

c. Omniversal milling machine

In addition to the table movement

obtained in a universal milling machine, the knee can be fited

to a required angle. It is useful for machining helical grooves, reamer and

bevel gears. It is mostly used in tool room work.

d. Vertical

milling machine

A spindle of a vertical milling

machine is positioned at right angles to the table. The cutter is moved

vertically or at an angle by swiveling the vertical

head of the machine. The machine is adapted for machining slots and flat

surfaces by moving the table. By mounting end mills and face milling cutters on

the spindle, vertical milling and internal milling are performed.

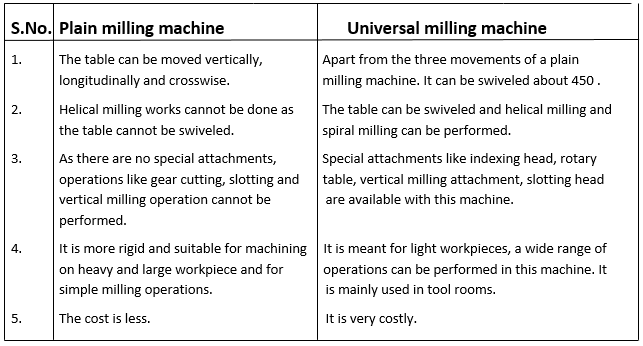

5 Differences between a plain milling machine and a universal

milling machine

6 Size of a

milling machine

The size of a milling machine is specified as

follows

1.

The size of the table (Length and width)

2.

The maximum lengths of longitudinal, cross and

vertical travel of the table.

3.

Number of spindle speeds, number of feeds.

4.

Spindle nose taper.

5.

Power required

6.

Nett weight of the machine

7.

The floor space required

8.

Type of the machine

7 Fundamental milling process

The various milling process may be grouped under

two headings

1.

Peripheral milling

2.

Face milling

Peripheral milling

The machining is performed by the cutting edges on

the periphery of the milling cutter. It is classified under two headings.

1.

Up milling

2.

Down milling.

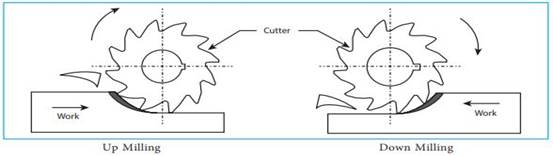

Up milling

In this method, the workpiece

mounted on the table is fed against the direction of rotation of the milling

cutter. The cutting force is minimum during the beginning of the cut and

maximum at the end of cut. The thickness of chip is more at the end of the cut.

At the cutting force is directed upwards. It tends to lift the workpiece from

the fixtures. A difficulty is felt in pouring coolant on the cutting edge. Due

to these reason the quality of the surface obtained by this methods is wavy.

This processes being safer is commonly used and sometimes called conventional

milling.

Down milling

The workpiece mounted on the

table is moved in the same directions as that of the rotation of the milling

cutter. The cutting force is maximum at the beginning and minimum at the end of

cut. The chip thickness is more at the beginning of the cut the workpiece is

not disturbed because of the bite of the cutter on the work. The coolant

directly reaches to the cutting point. So the quality of surface finish

obtained is high. Because of the backlash error between the feed screw of the

table and the nut, vibration is set up on the workpiece.

Face milling

During face milling, the

machining is performed by the peripheral cutting edges. The surface obtained by

the processes is perpendicular to the axis of rotation of the cutter.

End milling

End milling is a process of the

machining by milling cutters which have cutting edges both on the end face and

on the periphery.

8 Work holding devices

For effective machining

operations, the workpieces need to be properly and securely held on the machine

table. The following are the usual methods of holding work on the table. Large

and irregular shaped workpieces are held on the milling machine table by T

bolts and clamps. V blocks are used for holding cylindrical workpieces on

the machine table in which key ways, slots and flats are to be machined. Angle

plates are used to support the work when surfaces are to be milled at right

angles to another machined surfaces.

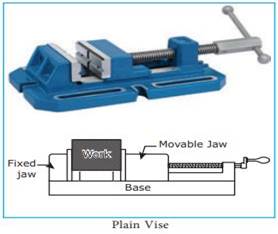

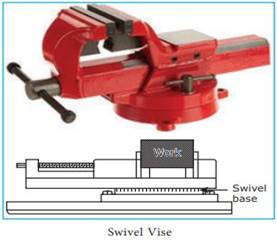

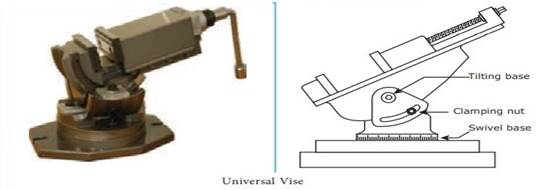

Vises are

commonly used for holding work on the table due to its quick loading and

unloading arrangement. There are mainly three types of vises

namely plain vise, swivel vise

and universal vise.

Milling fixtures are useful when

large numbers of identical workpieces are to be machined workpieces are held

easily, quickly and accurately by milling fixtures.

9 Cutter holding devices

Depending on the design of the

cutter there are several methods of supporting milling cutters on the machine

spindle.

1.

Arbor

2.

Collet

3.

Adapter

4.

Screwed on cutters

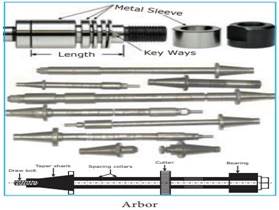

Arbor

Milling cutters with central

holes are mounted and keyed on a shaft called arbor.

There are three different types of arbor namely pilot

end arbor, A type arbor

and stub arbor.

The arbours are made with taper

shanks for correct alignment with the machine spindle the left side of the arbor is threaded internally to receive a draw bolt. This

draw bolt connects the arbor with the spindle. A long

key way is cut on the entire length of the arbor.

Cutters are mounted at desired positions on the arbor

by placing spacing collars between them. The spindle rotation is transmitted to

the arbor and the cutter is rotated. An arbor is illustrated in figure

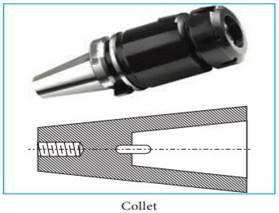

Collet

It is form of sleeve bushing used

to hold arbor or cutters having a smaller shank than

the spindle taper. Collets are connected to the spindle by a draw bolt and the

rotary motion is transmitted to the cutters.

Adapters

Milling cutters having shanks are

generally mounted on adapter. The outside taper of the adapter confirms to the

taper hole of the spindle. The shank of the cutter fits into the taper hole of

the adapter.

Screwed arbor

The small cutters having threaded

holes at the center are held by screwed arbors. It has a threaded nose at one end and adapters shank at the other end the shank of the arbor is mounted on the spindle.

10 Milling machine attachments

Milling machine attachments are

intended for purpose of developing the range of operations, versatility,

production capacity and accuracy of machining process. The different milling

machine attachments are

1.

Vertical milling attachments

2.

Universal milling attachments

3.

High speed milling attachments

4.

Slotting attachments

5.

Rotary table attachments

6.

Indexing head attachments

Vertical milling attachments

A horizontal milling machine is

converted into a vertical milling machine by the vertical milling attachment.

Vertical milling attachment is mounted on the face of the column of the

horizontal milling machine. The attachment along with the spindle can be

swiveled to any angle for machining angular surfaces.

Universal milling attachments

By having the universal milling

attachments the spindle of the machine can be swiveled about two perpendicular

axes. This arrangement permits two spindle axis to be swiveled at practically

any angle to machine any angular surface of the work.

High speed milling attachment

This attachment is used to

increase the regular spindle speeds by four to six times milling cutters of

smaller diameters are operated efficiently at higher cutting speeds. This

attachment is bolted to the face of the column and enables the cutter to be

operated at speeds beyond the scope of the machine.

Slotting attachment

The rotary movement of the

spindle is converted into reciprocating movement of the ram by a crank

arrangement. This attachment makes the milling machine to be converted into a

slotting machine by accepting a single point slotting tool. The tool is mounted

on the ram and used for cutting internal or external keyways, spline etc. It

can also be swiveled for machining angular surfaces.

Rotary table attachments

It is special device bolted on

top of the machine table to provide rotary motion to the workpiece in addition

to the longitudinal cross and vertical movements of the table. It consists of a

circular table provided with T- slots mounted on a graduated base. The

driving mechanism of this attachment is made possible by worm and worm gear.

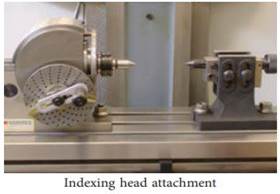

Indexing head attachment

It is a special work holding

device used for dividing the periphery of the work into any number of equal

divisions. The work is held in a check of the dividing head spindle or

supported between centres. It is also used in shaping machines and slotting

machines. While machining gears, spirals, clutches and ratchets this dividing

head is used to divide the circumference of the work into any number of equal

parts.

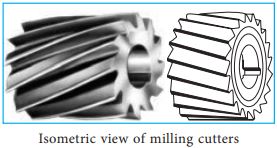

11 Isometric view of

milling cutters

Milling cutters are multipoint

cutters. Thease cutters are used to remove excess

material of given job by milling

12

Standard Milling Cutter

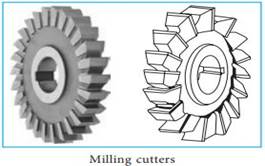

There are different types of

milling cutters used in a milling machine. A suitable milling cutter is selected

according to the need.

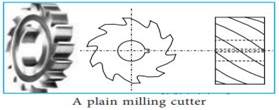

Plain milling cutter

Plain milling cutters are

cylindrical in shape and have teeth on the circumferential surface only. They

are used for producing flat surfaces parallel to the axis of rotation of the

spindle. The teeth of the cutter may be straight or helical according to the

size. If the width of the cutter is more, it is called as slabbing cutter in

order to be mounted on the arbor. Plain milling

cutters have nicked teeth to break the chips into small pieces. Helical plain

milling machine cutters are superior to a straight plain milling cutter.

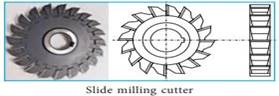

Side milling cutter

Side milling cutters have teeth

on its periphery and also on one or both of its sides. They are intended for

removing metal from the sides of the workpiece. There are different types of

side milling cutters namely face and side milling cutter, half side milling

cutter, staggered teeth side milling cutter and inter locked side milling

cutter. Machining is performed by selections a proper milling cutter.

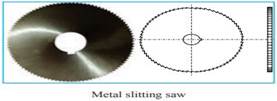

Metal Slitting saw

It is intended for cutting

narrow, deep slots and for parting off operation. The teeth are cut on the

circumference of the cutter. The width of the cutter ranges from 0.75 mm to 7

mm. The side of the cutter is relieved so that side may not rub against the

work

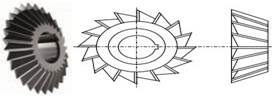

Angle milling cutters

The teeth of the angle milling

cutter are not parallel to the axis but are at an angle to it. By using angle

milling cutter, inclined surfaces, bevels and helical grooves are machined.

There are two types of angle milling cutter single angle milling cutters and

double angle milling cutter.

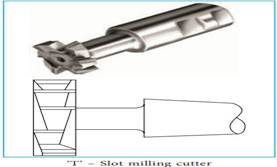

T Slot milling cutter

It is a special form of end mills

intended for machining T slots. It looks like a side milling cutter with a

shank. The cutters have cutting teeth on the periphery as well as on both sides

of the cutter.

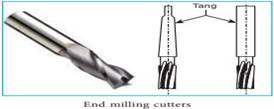

End mill Cutter

These cutters have cutting teeth

on the end as well as on the periphery of the cutter. It is made of two parts

body and shank. The shanks of the cutter may be straight or taper. If the

cutter doesnt have a shank it is called shell end milling cutter. These

cutters are useful in machining long narrow slots, holes and flat surface.

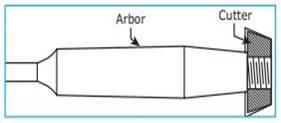

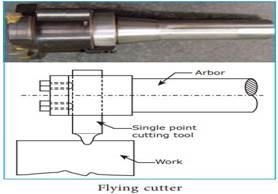

Flying cutter

Flying cutter is the simplest

form of cutter. It consists of a single point cutting tool attached to the end

of the arbor. The cutting edge may be formed to

reproduce a contoured surface. They are used when standard cutters are not

available. The work is done very slowly because of a single cutting edge. A

flying cutter is shown in Figure.

Form cutter

Form cutters have irregular

profiles on their cutting edges to produce required outlines on the work.

Concave and convex milling cutters are used to produce convex and concave

surfaces respectively using gear milling cutters. Gears are machined corner

round milling cutters are used for cutting a radius on the edges of the work

with the help of thread milling cutter threads are milled on a specific form

and size. Tap and reamer cutter are used for producing grooves or flutes in tap

and reamers.

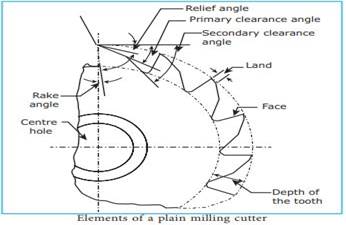

13 Elements of a plain milling

Cutter

The main parts and angles of a

plain milling cutter as shown in Figure.

Body of cutter

It is the part of the cutter left

after exclusion of the teeth.

Face

The portion of the teeth next to

the cutting edge is known as face.

Land

The relieved back portion of the

tooth adjacent to the cutting edge. It is relieved to avoid interference

between the surface being machined and the cutter.

Outside diameter

The diameter of the circle

passing through the peripheral cutting edges.

Centre hole

It refers to hole present at the

centre of cutter. A keyway is cut inside the hole.

Cutter angles

ή Relief angle

It

is the angle between land of the tooth and the tangent to the outside diameter

of the cutter at the cutting edge of the particular tooth. (Approx

7.50)

ή Primary clearance angle

It

is the angle between the back of the tooth and the tangent drawn to the outside

diameter of the cutter at the cutting edge (Approx 150 ).

ή Secondary Clearance Angle

It

is the angle formed by the secondary clearance surface and the tangent to the periphery

of the cutter at the cutting edge.

ή Rake angle

The

angle measured in the diametral plane between the

face of the tooth and a radial line passing through the cutting edge of the

tooth.

The

rake angles may be positive, negative or zero. If the face and the tooth body

are on the same side of the radial line and the tooth body may be on opposite

sides of the radial line. Then the rake angle is negative.

If

the radial line and the tooth face coincide in the diameter plane the rake

angle is zero.

14 Milling cutter material

The milling cutters are generally made of the

following materials.

1.

Tool steel High Speed Steel (HSS)

High Carbon Steel (HCS)

2.

Cemented carbide

3.

Stellite

In general shop work, the high

speed steel cutters are most widely used.

15 Milling machine operations

The following operations are

performed using suitable milling cutters

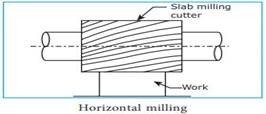

Horizontal milling

It is the operation of production

of a flat surface parallel to the axis of rotation of the cutter. It is also

called as slab milling, plain milling cutters and slab milling cutters are used

to perform this operation.

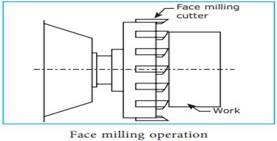

Face milling

The face milling is the operation

performed by the face milling cutter rotated about an axis at right angles to

the work surface. End mills and side & face milling cutters are also used

at times to perform this operation. The depth of cut is provided to the table.

Side milling

Side milling is the operation of

machining a vertical surface on the side of a work piece by using a side

milling cutter.

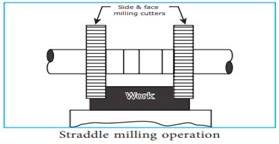

Straddle milling

It is the operation of production

of two vertical surfaces on both sides of the work by two side milling cutters

mounted on the same arbor. By using suitable spacing

collars, the distance between the two cutters are adjusted correctly. The

straddle milling is commonly used to produce square or hexagonal surface.

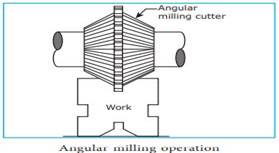

Angular milling

Production of an angular surface

on a workpiece other than at right angles to the axis of the milling machine

spindle is known as angular milling. Example of angular milling is the

production of the V blocks.

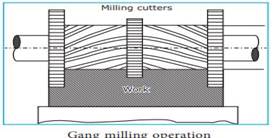

Gang milling

It is the operation of machining

several surfaces of work simultaneously by feeding the table against a number

of cutters (either of same type or of different type) mounted on the arbor of the machine. This method saves much of machining

time and mostly used in production work.

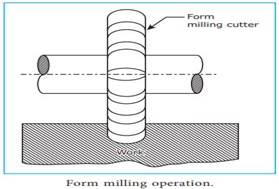

Form Milling

The form milling is the operation

of production of irregular contours by using from cutters. Machining convex and

concave surfaces and gear cutting are some examples of form milling.

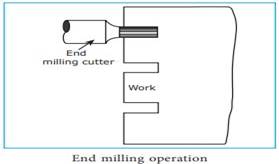

End milling

It is the operation of producing

a flat surface which may be vertical, horizontal or at an angle to the table

surface. The end milling is performed by a cutter known as an end mill. End

milling is mostly performed in a vertical machine.

Keyway milling

The operation of production of

keyways, grooves and slots of different shapes and sizes can be performed in a

milling machine by using a plain milling cutter, a metal slitting saw, an end

mill or by a side milling cutter.

Gear cutting

Gear cutting operation is

performed in a milling machine by using a form cutter. The work is held between

centers on a universal dividing head. A proper gear

cutter is selected and the teeth are cut by DP, module method.

Cam milling

Cam milling is the operation of

producing cams in a milling machine with the use of a universal dividing head

and a vertical milling attachment. It is performed by end mills on the cam

blank.

16 Cutting speed, feed and depth of cut

Cutting speed:

It is the distance travelled by a

point on the cutting edge of the milling cutters to remove metal in time

duration of one minute. It is expressed in meters per minute.

Cutting speed =

![]() meter/minute

meter/minute

![]() (or) 3.14,

(or) 3.14,

Where, D = The diameter

of the milling cutter in mm

N

= Spindle speed in rpm.

The cutting speed depends upon the material to be

machined, the cutter material, depth of cut, feed, type of operation and the coolant

used.

Example: Calculate the cutting speed to perform

milling with a cutter of diameter 60 mm and spindle speed of 250 rpm.

Solution :

Given Diameter of cutter (D) = 60 mm

Spindle

speed (N) = 250 rpm

Cutting speed =

![]() meter/minute

meter/minute

![]() (or) 3.14,

(or) 3.14,

![]()

![]()

Feed

The feed in a milling machine is defined as the

distance the workpiece advance under the cutter. Feed can be expressed in three

different methods.

1.

Feed per teeth:

It

is the distance the work advances in time between engagements by the two

successive teeth. It is expressed.

2.

Feed per cutter revolution:

It

is the distance the work advance in the time when the cutter turns through one

complete revolution. It is expressed in mm per revolution of the

cutter.

3.

Feed per minute:

It

is the distance the work advances in one minute. It is expressed in mm per minute.

The feed in a milling machine depends on the material to be machined, cutter

material, depth of cut, cutting speed, type of operation and the rigidity of

the machine.

Depth of cut

The depth of cut is the thickness

of the material removed in one pass of the work below the cutter. It is

expressed in mm.

17 Indexing head

Indexing is the method of dividing

the periphery of a piece of work into any number of equal parts. The attachment

used for performing indexing is known as indexing head.

Uses of indexing

The indexing operation can be

adapted for cutting gears, ratchet wheels. Keyways, fluted drills taps and

reamers. The indexing head serves as an attachment for holding and indexing the

work in during the above tasks. There are three different types of indexing

heads namely

1.

Plain or simple dividing head

2.

Universal dividing head

3.

Optical dividing head

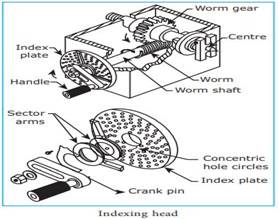

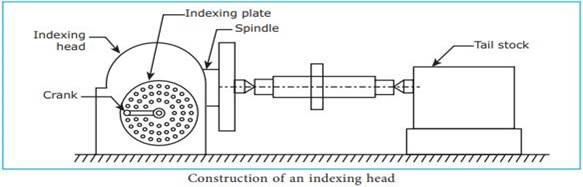

18 Construction of indexing head

The construction of a universal dividing head as

shown in figure and explained below.

Base

The base of the indexing head is

fitted in the T slots of the milling machine table. It supports all the

other parts of dividing head.

Spindle

The spindle is situated at the

centre of the dividing head. It has a taper hole to receive a live center. The spindle is supported on a swiveling

block, which makes the spindle to be tilted through any angle from 50 below horizontal

to 100 beyond vertical. A worm wheel is mounted on the spindle. While doing

direct or rapid indexing the index plate is directly fitted on the front end of

the spindle nose.

Worm shaft

It is situated at right angles to

the main spindle of the dividing head. A single threaded worm is mounted on the

worm shaft which meshes with the worm wheel. An indexing plate is fitted on the

front end of the worm shaft and with the help of a handle, the worm shaft can

be rotated to a pre determined amount.

Indexing Plate

It is mounted on the front end of

the worm shaft. It is circular disk having different numbers of equally spaced

holes arranged in concentric circles. The crank is positioned in the required hole circle and rotated through a calculated amount while

indexing. The sector arm is used to eliminate the necessity of counting the

holes on the index plate each time the index crank is moved.

Tail Stock

The work is held between the center of the spindle and the tailstock. It can be made

slide and positioned at the required location.

Working principle of dividing head

When the crank is rotated with

help of a handle through the required number of holes in the index plate. The

work is rotated to required amount. This is possible because of the worm and

worm wheel mechanism.

A

gear train is arranged between the main spindle and the driven shaft when

indexing is done by differential indexing method. The work is rotated as usual

when the handle is rotated. At the same time, the index plate is also made to

rotate a small amount through the gear train when indexing is by this

differential indexing method, the index plate is released from the lock pin.

19 Indexing methods

There are several methods of indexing and they are

1.

Direct or rapid indexing

2.

Plain or simple indexing

3.

Compound indexing

4.

Differential indexing

5.

Angular indexing

20 Safety precautions

Before operating the milling

machine, the operator should know how to operate various controls of the

machine. It should be ensured that the workpiece is held rigidly on the milling

machine table. The cutter should not be in contact with the work even before

the machining is commenced.

The spindle speed of machine

should not be altered when the machine is in operation. When the power of the

machine table is on the arbor should not be removed

or tightened. The operator should keep his body away from the rotating cutter.

No steps should be taken to measure the workpiece while the cutter is cutting

or revolving near the workpiece when the machine is in operation, safety guards

should be placed in their position to prevent coolant and metal chips from

spilling out.

The metal chips should be removed

with suitable brushes and with bare hands. The operation should seek assistance

from others while handing special attachments and heavy workpieces. The

operator should always be present in person at the machine tool when the

machine is in operation.

The machine tool should always be

started and stopped by the operator himself. Dangers can be averted by handling

the cutters with sharp cutting edges with great care. The machine tool should

be kept clean. Milling cutters and measuring instruments should not be placed

on the machine. The attention of the operation should always be focused on the

task only. When troubles happen in the machine, they should be corrected with

assistance of proper technicians in general safety should be ensured to the

operator, the workpiece and the cutting tool.