Welding

Introduction

Welding can be defined as the

process of joining two metal parts by applying heat. In industry, welding

process is primarily used for fabricating works.

Welding

is useful in making permanent joints. It can be performed by applying or not

applying pressure. In some types of welding processes, filler metal is used. In

some other methods, filler metal is not used.

The

process of welding finds application in manufacturing automobiles, aeroplanes,

rail coaches, machine components, metal structures, boilers and ships.

Generally, welding process is applied wherever metal works are performed.

Types of Welding

There are two types by which welding is performed

1.

Plastic welding

2.

Fusion welding

Plastic Welding

In

this type, the metal parts are heated to plastic state. In this stage, pressure

is applied to make a perfect joint. It is also known as pressure welding.

Fusion Welding

The metal parts are heated upto

the point of melting in this type. The joint is made at this stage and the

parts are allowed to cool. On cooling, the molten metal forms a solid joint. No

pressure is applied in this method. Hence, it is also known as pressure less

welding or Fusion welding Arc welding and gas welding fall in this category.

Classification of welding processes

1.

Arc welding

a. Carbon arc welding

b. Metal Arc welding

c. Metal Insert gas welding

d. Tungsten inert gas welding

e. Atomic hydrogen welding

f. Plasma arc welding

g.

Submerged welding

h. Electro slag welding

2.

Gas Welding

a. Oxy – acetylene welding

b. Air – acetylene welding

c. Oxy hydrogen welding

3.

Oxy – acetylene cutting

a. Arc cutting

b. Hard facing

c. Brazing d. Soldering

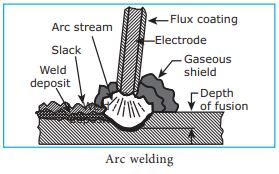

Arc welding

In

arc welding, the edges of two metal parts are melted by an electric arc and the

joint is made. An electrode made of a suitable metal is utilised for this

purpose. The electrode is taken closer to the parts to be joined and electric

current is supplied to both the parts and the electrode. An electric arc is

made between the electrode and the metal parts. This arc generates high

temperature and melts the metal parts. The parts are joined at this molten

state. The filler metal in the form of electrode is deposited along the joint.

The metal parts are joined without the application of any pressure. Electrical

energy is converted into heat energy in arc welding.

Electric Arc welding

The distance between the metal

parts and the electrode should be around 3mm. The heat generated during arc

welding ranges from 50000 C to 60000 C. A generator or a

transformer supplies the required current to both the electrode and the metal

parts. The electrodes are flux coated to prevent the molten metal from reacting

with the atmosphere.

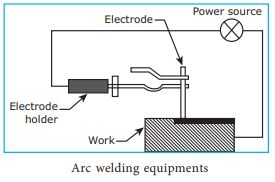

Arc welding equipments

The following equipments are used for the process

of arc welding

i.

D.C welding generator (or) AC transformer

ii.

Cables

iii.

Electrode cable

iv.

Work cable

v.

Electrode holder

vi.

Electrode

vii.

Gloves

viii.

Protective shield (or) Goggles

ix.

Apron for the operator

x.

Wire brush

xi.

Chipping hammer

Differences between DC generator and AC transformer

|

DC generator |

AC transformer |

|

Low

efficiency |

High efficiency |

|

High

power cost |

Low power cost |

|

High

machine cost |

Low machine cost |

|

Runs

on low voltage |

Runs on high voltage |

|

Safe

equipment |

The chances of accidents is

high |

|

Uncoated

electrodes may be used |

only flux coated electrodes are used |

|

DC generator |

AC transformer |

|

Joints

are made with ferrous and nonferrous metal parts |

Non-ferrous metal parts cannot

be joined |

|

Noisy

functioning |

No noise during operation |

|

The

cost of the process is low |

High process cost |

|

Easy

maintenance of equipments |

Requires proper maintenance |

|

Thin

metal parts can easily be welded |

Difficult to weld thin parts |

Specification of electrodes

Electrodes

- figure

Generally, the size of the

electrodes is specified by the length and its diameter. They are available to a

maximum of 12 mm diameter and 45mm length. The size of the electrode increases

with the current used. In manual welding, the size of the electrode changes

according to the thickness of the metal parts. Spring like electrodes are used

in automatic welding

Types of electrode

The electrodes used in arc welding are two types

1.

Consumable electrode

2.

Non – consumable electrode

There are three types of consumable electrodes.

They are

1.

Bare electrodes

2.

Lightly coated electrodes

3.

Heavily coated electrodes

Non – consumable electrodes are used in the processes

of atomic hydrogen welding and TIG welding

Selection of electrodes

The material used for manufacturing electrodes

depends upon the material to be welded. Given is the list indicating suitable

materials for manufacturing electrodes for welding different metals.

|

S.

No Material to be welded |

Electrode

material |

|

1 Wrought iron Low Carbon Steel Rod 2 Mild Steel Mild Steel, Copper coated

Rod 3 Alloy Steel Nickel Steel Rod 4 Cast Iron Cast Iron Rod 5 Aluminium Cast Aluminium Alloy Rod 6 Carbon Steel Steel wire (0.15% Carbon &

0.025%) Phosperous

& Sulphur 7 Copper Copper Rod 8 Brass Brass Rod |

|

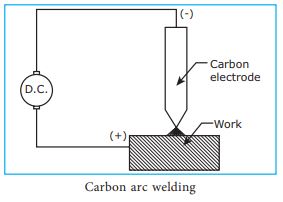

Carbon arc welding

In carbon arc welding, the

process of welding is carried out by an electric arc. The arc formed between

the electrode and the work piece generates high amount of heat. In D.C electric

supply, the carbon electrode is connected to the negative terminal and the positive

terminal is connected to the work piece. During the formation of the electric

arc, the temperature of the positive terminal is 40000 C and the

negative terminal will be around 30000 C. Carbon, the electrode

material will not fuse with the work piece materials. This prevents the joint

from becoming weak. A lengthy arc produces carbon – monoxide at the location of

welding and prevents the molten metal from reacting with the atmospheric air.

Both ferrous and non- ferrous

metals can be welded by this method. Steel sheets, copper and its alloys, brass

and aluminium parts are welded using carbon arc welding. This method of welding

can also be done automatically. Starting of the electric arc is easy and the

temperature is controlled easily. The disadvantage of this method is the

presence of blow holes in the joint.

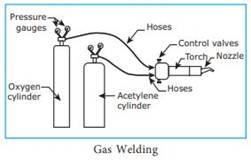

Gas welding

Gas welding is the process of

melting and joining metal parts by means of a gas flame. Generally pressure is

not applied during the process of gas welding. Oxygen and acetylene gases are

made to pass through the welding torch. These gases are mixed at the required

ratio at the torch and the tip of the welding torch is ignited to produce the

flame. Because of the heat generated by the flame, the edges of the metal parts

are melted. Filler rod provides the additional metal required for making the

joint. The flux coated on the electrodes prevents oxidation and removes

impurities. This method is suitable in welding metal parts of thickness varying

from 2mm to 50mm. The temperature of the flame is around 32000 C.

Gas welding equipments

The following equipments are necessary for gas

welding

1.

Gas cylinders

2.

Regulators

3.

Pressure gauges

4.

Rubber hoses

5.

Welding torch

6.

Safety goggles

7.

Gloves

8.

Spark lighter

9.

Wire brush

Gas cylinders

Oxygen

and acetylene gases are stored in separate cylinders and used for gas welding.

The colour of oxygen cylinder is black and the acetylene gas is stored in

maroon cylinders. Oxygen is stored at a pressure of 125kg/cm2.

Acetylene gas is stored at a pressure of 16Kg/cm2. In the cylinder.

Regulators

Separate

regulators are fitted on both the cylinders. A regulator is used to control the

working pressure of the gases. The working pressures of oxygen is 1Kg/cm2

and acetylene is 0.15Kg/cm2. Working pressure of these gases are

altered according to the thickness of the metal parts of the joint.

Two pressure gauges are fitted

each on the oxygen cylinder and on the acetylene cylinder. One of the pressure

gauges indicates the pressure of the cylinder and the other gauge indicates the

working pressure of the specific gas.

Hoses

Separate

hoses are used to connect the two cylinders with the welding torch through

regulators. The colour of the hose from the oxygen cylinder is black and the

one from the acetylene cylinder is red. These hoses carry the gases to the

welding torch.

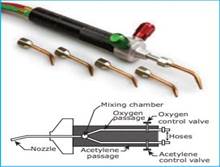

Welding torch

Oxygen

and acetylene reach the welding torch through the passages of hoses from the

respective cylinders. These gases are mixed in the mixing chamber of the

welding torch. Flame is produced at the tip of the torch when the gases are

ignited. There are two control valves present in the torch to control the

quantity of oxygen and acetylene. By this control, the grade of the flame can

be altered. The size of the flame is altered to suit the thickness of the metal

parts.

Goggles

Oxy

acetylene flame emits ultraviolet and infrared rays. These rays are highly

harmful to bare eyes. In order to protect the eyes of the welder, goggles

should be used by him.

Welding gloves

Protective

hand gloves are used by the operator to prevent possible damages that may be

caused by high temperatures and metal splashes during welding.

Spark lighter

Spark

lighter is used to ignite the oxyacetylene gas at the tip of the welding torch.

Wire brush

Wire

brushes are useful for cleaning the weld before and after the welding process.

Types of gas flame

The

size of the flame can be altered by varying the ratio of oxygen and acetylene. By

doing so, the following three types of flames are obtained.

1.

Neutral flame

2.

Carburising flame

3.

Oxidising flame

Neutral flame

The supply of equal quantities of oxygen and

acetylene produces neutral flame. There are two zones in this flame-

1.

Sharp and bright inner cone and

2.

Bluish outer cone.

The temperature of the inner cone

will be around 32000 C. This neutral flame is generally used as it will not

cause any chemical reaction upon the heated metal.

Carburising flame

This flame is also known as reducing flame. The

supply of acetylene will be more than oxygen to produce this flame. Carburising

flame consists of three zones namely,

1.

Sharp inner cone

2.

White intermediate cone

3.

Bluish outer cone

Carburising

flame is useful in welding low carbon steel and alloy steels. It is also used

to harden the outer surface of metal parts.

Oxidising flame

Oxidising

flame is obtained by supplying more oxygen than acetylene. It consists of two

zones namely bright inner cone and outer cone. This flame is useful in welding

brass and bronze.

Filler rods used in gas welding

Filler

rods used in gas welding supply the additional metal is making joints. These

rods are melted by the gas flame and deposited over the parts of the joint.

Generally the filler rods are made of the same metal as that of the parts of

the joint.

The

diameter of the filler rod depends upon the thickness of the parts to be

welded. The strength of the welding joint is increased by adding Nickel or

Chromium in filler rods. A thin coat of copper is provided on the filler rods

to prevent the molten metal from reacting with atmospheric oxygen. Flux may be

applied either in powdered form or liquid form.

Advantages of gas welding

1.

Applied for different classes of work

2.

Welding temperature is controlled easily

3.

The quantity of filler metal added in the joint

can easily be controlled

4.

The cost of the welding unit is less

5.

The cost of maintenance is less

6.

Both welding and cutting can be done

Disadvantages of gas welding

1.

Intended for welding thin work pieces only

2.

The process of welding is slow

3.

The time taken by the gas flame to heat the metal

is more when compared with electric arc.

4.

The strength of the joint is less

5.

Great care should be taken in handling and storing

gas cylinders.

Differences between arc welding and gas welding

|

Arc welding |

Gas welding |

|

The

heat is generated by the electric arc |

The required heat is provided

by the gas flame. |

|

The working

temperature is about 40000 C |

The temperature of the gas flame is about 32000

C |

|

The

filler rod is used as electrode. |

Filler rod is used separately |

|

Care

should be taken against the dangers |

The danger of the process is because of the

gases that may be caused because of electricity at high pressure |

|

The

strength of the joint is more |

The joint is not as strong as

that of arc welding |

|

Brazing

and soldering cannot be performed with the gas flame. |

The processes of brazing and soldering can be

done by the electric arc. |

|

The

filler rod metal should be selected as the joint. |

The filler rod metal can be

different from that of the the same metal as that of the parts of parts of

the joint |

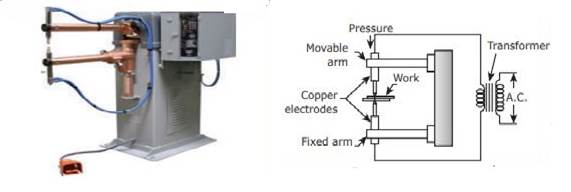

Resistance

welding

The process of resistance welding

involves developing electrical resistance in the parts of the joint to bring

them into a plastic state and Applying pressure on the parts to make the joint.

Two

copper electrodes are connected to an electric circuit of low resistance. The

parts to be welded are placed between the electrodes. When current is allowed

to pass through the electrodes, high electrical resistance is developed at the

joint. Because of the resistance, heat is generated at the joint. The metal

parts reach plastic state at this high temperature.

At

this point, pressure is applied by means of either mechanical or hydraulic or

pneumatic power source to make the joint. Current is provided by a suitable

A.C. transformer. Resistance welding is useful in welding sheet metal, bars and

pipes.

Welding related processes

Following are some important welding related

processes used in industries.

1.

O x y - a c e t y l e n e cutting

2.

Arc cutting

3.

Hard facing

4.

Soldering

5.

Brazing

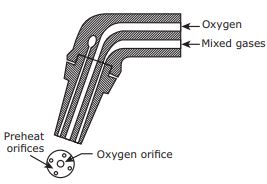

Oxy-acetylene cutting

Plates

made of iron and steel are cut by oxygen, acetylene cutting torch. Oxygen and

acetylene are mixed in the cutting torch and a gas flame is generated. The

flame heats the sheets to bring them to red hot condition. High pressure oxygen

is supplied on the red hot metal through a separate central hole of the cutting

torch. Iron and steel sheets are thus cut by the jet of oxygen.

Arc cutting

In this process, the metal parts are

heated by means of carbon or metal electrodes. High pressure air is supplied on

the molten metal to remove it and cut the metal parts. Oxygen jet is supplied

along with the electrode instead of air nowadays. Arc cutting is not suitable

for accurate work.

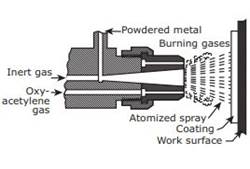

Hard facing

Hard

facing is a process of coating a hard material on soft metal parts. Powdered

coating metal is filled in the welding gun. The metal powder is melted by the

oxy-acetylene gas flame. The supply of inert gas at pressure makes the powdered

metal to split into small particles. These particles are sprayed on the

surfaces of the soft metal. Coatings of Tungsten carbide, Chromium carbide and

Aluminium oxide can be made on the surfaces of different cutting tools and

cutters.

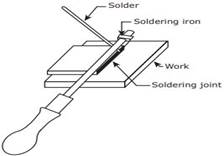

Soldering

Two

parts made of similar or dissimilar metals are joined by a solder made of a

fusible alloy. Solder is an alloy made of Tin and Lead. The melting temperature

of the solder is in the range of 1500 C to 3500 C. The

surfaces of the two metal parts are cleaned and held in correct positions. Flux

paste made of zinc chloride is applied on the parts by soldering iron.

Application of flux prevents oxidation. The solder is melted by the heat

provided by the soldering iron and filled between the metal parts. The solder

solidifies and joints the metal parts.

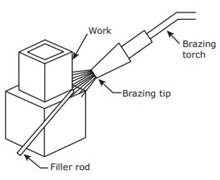

Brazing

In

brazing, filler metal in molten state is filled between the metal parts of the

joint. The filler rod is heated up to 4500 C. The parts to be joined

are cleaned and the molten filler metal is applied between the parts to make

the joint. In this method, the metal parts are not melted.

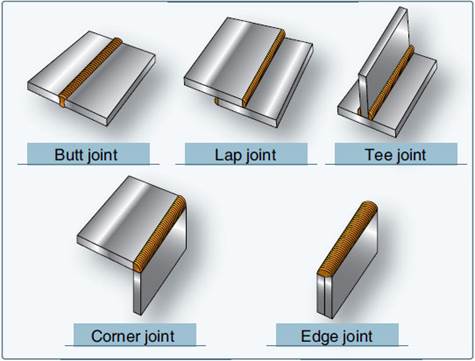

Types of welding joints

Following are the various types of welded joints

1.

Butt joint

2.

Lap joint

3.

T-joint

4.

Corner joint

5.

Flange joint

Butt joint

Butt

joint is a joint in which the corners or the edges of two metal parts are

joined. The process is done by keeping the metal parts on a same plane. The

edges of metal parts of thickness upto 5mm may be kept Open Square. If the

thickness of the metal parts exceeds 5mm, edges of the parts need to be

prepared in proper shape before welding.

Lap Joint

It

is a joint in which the metal plates are placed over lapping before welding.

The edge of one part is welded with the surface of the other plate. There are

two types of lap joint namely

(i)

single lap joint and

(ii)

Double lap joint.

T-Joint

This

joint is made by keeping the metal plates at perpendicular (900

) to each other. Sheets with thickners over

3mm only are welded by this type of joints.

Corner joint

Two

metal sheets kept at 900 to each other are welded by this joint. This method is

adopted when making boxes and tanks. Corner joints are adopted for thin and

thick sheets.

Flange joint

The

plates of the joint may be kept parallel or at 900 to each other. The edges of

the plates are bent to form the shape of a flange.

Safety precautions for welding

We

make use of electrical devices and inflammable gases like oxygen and acetylene

in welding. If proper care is not shown in handling them, there is always a

possibility of accidents taking place. So, welding process should be carried

out with due safety and caution.

Safety precautions for gas welding

1.

Gas cylinders should be kept in ventilated

locations.

2.

Cylinders should not be kept near hot locations.

They should be kept away from electrical terminals.

3.

Pressure regulators should be closed after the

welding work is completed.

4.

Regulators should be handled properly.

5.

Old and worn out regulators should be replaced

immediately.

6.

The operator should wear goggles, gloves, apron

and proper footwear.

7.

Fire extinguishers and first – aid box should be

kept ready always.

Safety precautions for arc welding

1.

The welder should always wear goggles. Gloves,

apron and proper footwear during welding

2.

Welding shop should be located properly so that it

does not cause any discomfort to others.

3.

The welder should act carefully against electric

shocks.

4.

A high quality electrode holder should be put into

use.

5.

Power supply should be provided at required voltage

and uniform current

6.

Fire extinguishers and First – aid box should

always be kept ready in a welding shop.