Preparation of Dihydrogen

Molecular hydrogen, sometimes called dihydrogen, is a diatomic molecule that is composed of two hydrogen atoms

held together by a covalent bond with the chemical formula H2.

Preparation

of Dihydrogen:

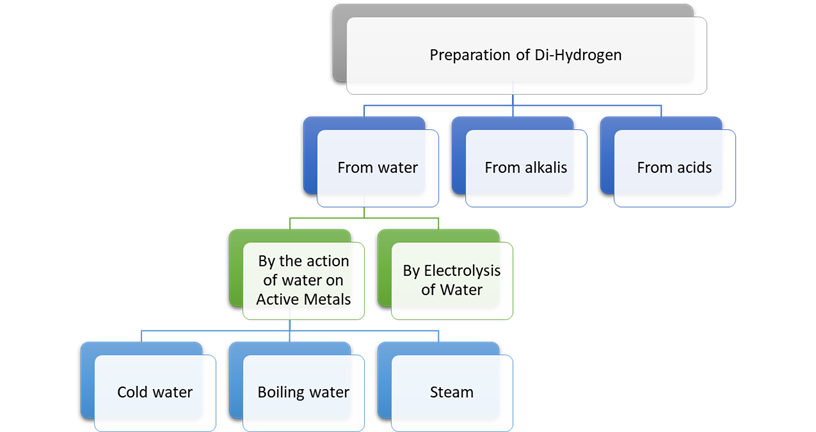

Dihydrogen may be obtained from water by reduction either with active

metals or by electricity. It can be prepared from three sources:

1. from water

2. from alkalis

3. from acids

1. From Water:

a) By the

Action of Water on Active Metals:

·

Cold Water: Very active metals i.e. alkali and certain alkaline earth metals like

Na, K , Ca react with water at room temperature evolving dihydrogen.

The reaction with

alkali metal is so vigorous and exothermic that the hydrogen involved catches

fire. To slow down the reaction, amalgams of these metals are generally used.

In amalgams, only a

small surface area of the metal comes in contact with water and therefore the

reaction is slowed down.

·

Boiling water: Less active metals like Zn, Mg, Al decompose boiling water liberating dihydrogen.

|

Zn + H2O |

→ |

ZnO + H2 |

|

Mg + H2O |

→ |

MgO + H2 |

|

2Al + 3 H2O |

→ |

Al2O3+

H2 |

·

Steam: Still less active metals like Fe, Sn, Ni

decompose steam at high temperature (1023-1073K) evolving dihydrogen.

|

3Fe + 4H2O → Fe3O4 +

H2 |

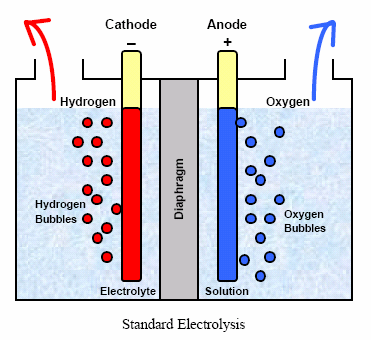

b) By

Electrolysis of Water:

Dihydrogen of high purity is usually obtained by the electrolysis of

water in the presence of small amount of an acid or a base. During

electrolysis, dihydrogen is collected at cathode while dioxygen is liberated at

anode.

|

2H2O (l)

→ 2H2 (g) + O2 (g) |

Pure water is only

weakly ionized and hence is a poor conductor of electricity but presence of an

acid or a base makes it a better conductor of electricity.

This method is not

commercially used since it is quite expensive.

2. From Alkalis:

Metals like Be, Zn, Sn react with

boiling alkali solution liberating dihydrogen.

|

Zn + 2NaOH |

→ |

Na2ZnO2 + H2 |

|

Be + 2NaOH |

→ |

Na2BeO2 + H2 |

|

Sn + 2NaOH

+ H2O |

→ |

Na2SnO3 + H2 |

|

2Al + 2NaOH

+ 2 H2O |

→ |

2NaAlO2 + 3H2 |

3. From Acids:

Metals which are more electropositive than hydrogen (lie above hydrogen

in the electrochemical series) such as Zn, Fe, Mg

react with dilute mineral acids to liberate dihydrogen gas.

|

Zn + H2SO4 |

→ |

ZnSO4 + H2 |

|

Fe +2HCl |

→ |

FeCl2 + H2 |

Metals like

Copper, silver, Mercury which are less electropositive than hydrogen (lie below

hydrogen in the electrochemical series) do not liberate hydrogen from acids.

There

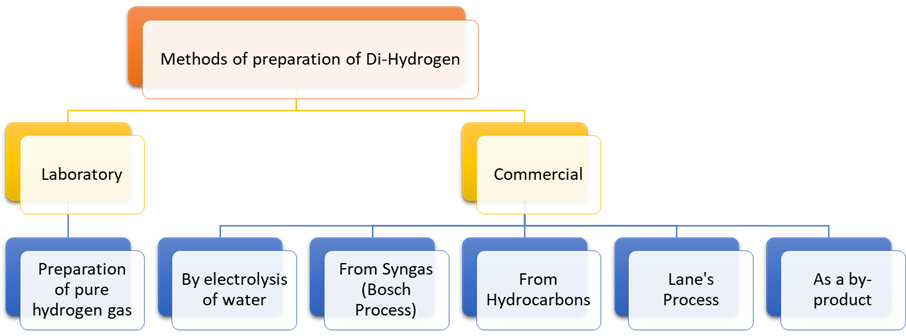

are two methods in preparation of dihydrogen:

1. Laboratory preparation

2. Commercial preparation

1. Laboratory Preparation:

In laboratory, dihydrogen is

prepared by reaction of dil H2SO4 on

granulated zinc.

|

Zn + H2SO4 → ZnSO4 +

H2 |

Granulated pieces of

zinc are placed in a Woulfe’s bottle and are covered

with water. The bottle is fitted with a thistle funnel and a delivery tube.

Conc.H2SO4 is poured slowly through the

thistle funnel. As the acid falls in the Woulfe’s bottle,it gets diluted and then

reacts with zinc evolving dihydrogen gas. It is collected by downward

displacement of water.

Sometimes the bubbles of dihydrogen produced stick to the surface of the

zinc metal preventing the further reaction of the acid on the metal. Such a

situation can be avoided by adding few crystal of copper sulphate to the

reaction mixture.

Preparation

of Pure Dihydrogen Gas:

·

By the action of pure

sulphuric acid on magnesium ribbon

|

Mg + H2SO4 (dil) → MgSO4 + H2 |

·

By the electrolysis

of a warm solution of barium hydroxide using platinum or Nickel electrodes

·

By the action of

water on sodium hydride

|

NaH + H2O

→ NaOH + H2 |

·

By the action of KOH

on scrap aluminium

|

2Al + 2KOH + 2H2O → 2KAlO2 +

3H2 |

2. Commercial

Preparation:

· By the Electrolysis of Water:

A small quantity of

acid or alkali is added to water to make it a good conductor and electrolysed

in a cell. In this cell, iron sheet is used as a cathode while nickel plated

iron sheet act as anode.

The two electrodes are separated from each other by an asbestos diaphragm which prevents

mixing of dihydrogen and dioxygen. On passing electric current, dihydrogen gas

is collected at cathode while dioxygen at anode.

When 20% NaOH solution is used for electrolysis, the decomposition

of water takes place as follows:

At cathode,

|

H+ +

e‾ |

→ |

H |

|

H+ +

H+ |

→ |

H2 |

At anode,

|

4OH‾ |

→ |

4OH + e‾ |

|

4OH‾ |

→ |

2H2O

+ O2 |

· From Syngas

(Bosch process):

When superheated steam is passed

over red hot coke or coal at 1270K in the presence of nickel catalyst, a

mixture of carbon monoxide and dihydrogen is produced.

|

C (s) + H2O

(g) → CO + H2 |

A mixture 1:1 of CO

and H2 was called water gas. All mixtures of CO and H2irrespective

of their composition are called synthetic gas or syngas.

This process of

producing syngas from coke or coal is coal gasification.

Syngas is produced

from sewage, sawdust, scrap wood, newspaper.

It is difficult to obtain pure hydrogen from water gas or Syngas, since

CO is difficult to remove. To remove CO and increase the production of

dihydrogen from syngas, CO of the syngas is oxidised to CO2 by

mixing it with more steam at 673 K in presence of iron chromate as catalyst.

|

CO (g) + H2O

(g) + H2O (g) → CO2 (g) + 2H2 (g) |

CO2 thus produced is removed either by scrubbing the

mixture with sodium arsenide solution or bypassing the mixture through water

under 30 atm pressure when carbon dioxide dissolves

leaving behind dihydrogen which is collected.

· From

Hydrocarbons:

Partial Oxidation of

Hydrocarbons: A mixture of hydrocarbons is mixed with steam and

passed over heated Nickel catalyst at 1270 K.

|

CnH2n+2 +

nH2O → nCO + (2n+1) H2 |

Natural gas may also

be used.

|

CH4 (g) + H2 (g) |

Whole process of

obtaining dihydrogen from natural gas is called steam

reforming process.

Thermal Cracking of Natural Gas: Dihydrogen may also be obtained by thermal cracking of natural gas at

1270 K in the presence of a catalyst.

|

CH4 → C + 2 H2 |

· Lane’s

Process:

Dihyrogen

can also be manufactured by passing alternate currents of steam and water gas

over red hot iron. It consists of two stages:

Oxidation Stage: Super heated steam is passed over iron filling heated to about 1023 – 1073 K when

hydrogen is formed and magnetic oxide of iron is left behind.

|

3Fe + 4 H2O

→ Fe3O4 + 4H2 |

Reduction stage: When the whole of iron has being

oxidised, the steam supply is cut off and a steam of water gas is passed to

reduce Fe3O4 back to iron.

|

Fe3O4

+ 4H2 |

→ |

3Fe + 4H2O |

|

Fe3O4

+ 4CO |

→ |

3Fe + 4CO2 |

By passing steam and

water gas alternatively over heated iron, dihydrogen gas can be manufactured

from a small quantity of iron.

· As a By –

Product:

Large quantities of dihydrogen are

obtained as a by-product in various industries.

1) From petroleum

cracking plants

2) In the manufacture

of sodium hydroxide and chlorine by electrolysis of brine solution.

At anode,

|

2Cl‾ (aq) → Cl2

(g) + 2e‾ |

At Cathode,

|

2H2O

(l) + 2e‾ → H2 (g) + OH‾ (aq) |

Overall

reaction:

|

2Cl‾ (aq)

+ 2H2O (l) → Cl2 (g) + H2 (g) + OH‾ (aq) |