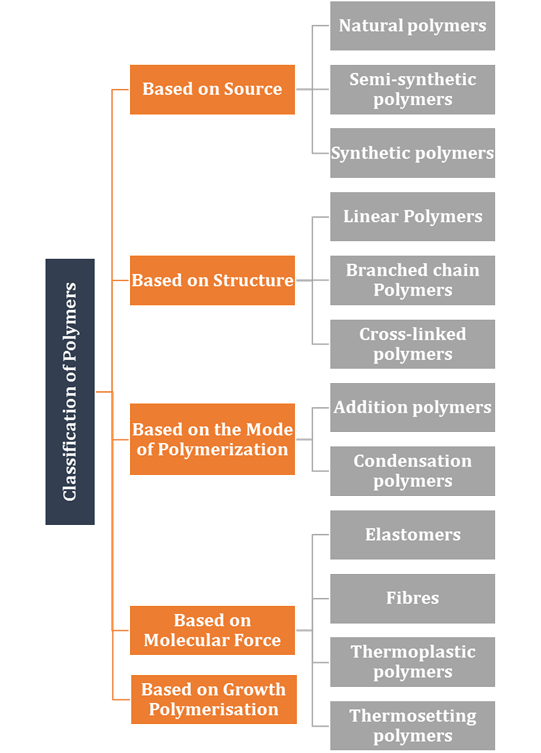

Classification

of Polymers

There are several ways of classification of polymers

based on some special considerations. The following are some of the common

classifications of polymers:

Classification based on source

Natural polymers

Ø

Natural polymers are polymers which occur in

nature

Ø

These polymers are found in plants and animals.

Ø

Examples are proteins, cellulose, starch, some resins

and rubber.

Semi-synthetic

polymers

Ø

Semi-Synthetic polymers are polymers obtained by

making modification in natural polymers artificially in a lab.

Ø

These polymers formed by chemical reaction (in a

controlled environment) and are of commercial importance.

Ø

Cellulose derivatives as cellulose acetate (rayon) and

cellulose nitrate, etc. are the usual examples of this sub category.

Synthetic

polymers

Ø Synthetic polymers are polymers which humans can

artificially create/synthesize in a lab.

Ø These are commercially produced by industries for

human necessities.

Ø Examples of manmade polymers extensively used in daily

life as well as in industry are plastic (polythene), synthetic fibres (Nylon-

6, 6) and synthetic rubbers (Buna - S).

Classification

based on structure of polymers

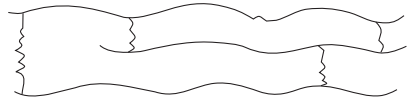

Linear

Polymers

Ø

These polymers consist of long and straight chains.

Ø

The examples are high density polythene, polyvinyl

chloride, etc.

Ø

These chains do not have any side chain.

Ø

These are represented as:

Branched

chain Polymers

Ø

These polymers contain linear chains having some

branches.

Ø

For example, low density polythene.

Ø

These are depicted as follows:

![]()

Cross-linked

or Network polymers

Ø

These are usually formed from bi-functional and

tri-functional monomers.

Ø

They contain strong covalent bonds between various

linear polymer chains, e.g. Bakelite, melamine, etc.

Ø

These polymers are depicted as follows:

Addition polymers

Ø

The

addition polymers are formed by the repeated addition of monomer molecules

possessing double or triple bonds, e.g., the formation of polythene from ethene and polypropene from

propene. However, the addition polymers formed by the polymerisation of a

single monomeric species are known as homopolymers,

e.g., polythene.

![]()

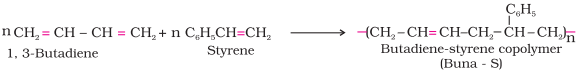

Ø

The

polymers made by addition polymerisation from two different monomers are termed

as copolymers, e.g., Buna-S, Buna-N, etc.

Condensation polymers

Ø The condensation polymers are formed by repeated

condensation reaction between two different bi-functional or tri-functional

monomeric units.

Ø In these polymerisation reactions, the elimination of

small molecules such as water, alcohol, hydrogen chloride, etc. take place.

Ø The examples are terylene

(dacron), nylon 6, 6, nylon 6, etc. For example,

nylon 6, 6 is formed by the condensation of hexamethylene

diamine with adipic acid.

![]()

Classification based

on molecular forces

Elastomers

Ø These are rubber – like solids with elastic

properties.

Ø In these elastomeric polymers, the polymer chains are

held together by the weakest intermolecular forces.

Ø These weak binding forces permit the polymer to be

stretched.

Ø A few ‘crosslinks’ are introduced in between the

chains, which help the polymer to retract to its original position after the

force is released as in vulcanised rubber.

Ø The examples are buna-S, buna-N, neoprene, etc.

Fibres

Ø Fibres are the thread forming solids which possess high

tensile strength and high modulus.

Ø These characteristics can be attributed to the strong

intermolecular forces like hydrogen bonding.

Ø These strong forces also lead to close packing of

chains and thus impart crystalline nature.

Ø The examples are polyamides (nylon 6, 6), polyesters (terylene), etc.

Thermoplastic polymers

Ø These are the linear or slightly branched long chain

molecules capable of repeatedly softening on heating and hardening on cooling.

Ø These polymers possess intermolecular forces of

attraction intermediate between elastomers and fibres.

Ø Some common thermoplastics are polythene, polystyrene,

polyvinyls, etc.

Thermosetting polymers

Ø These polymers are cross linked or heavily branched

molecules, which on heating undergo extensive cross linking in moulds and again

become infusible.

Ø These cannot be reused.

Ø Some common examples are bakelite,

urea-formaldelyde resins, etc.

Classification based on growth

polymerisation

The addition and condensation polymers are nowadays also

referred as chain growth polymers and step growth polymers depending on the

type of polymerisation mechanism they undergo during their formation.

|

Po Polymer |

La large

molecules having high molecular mass formed by combination of number of small

units called monomers. |

|

P Polymerisation |

Th The process of formation of polymers from respective monomers. |

|

Na Natural polymers |

Fofound in plants and animals. Examples: proteins, cellulose, starch. |

|

Sy Synthetic polymers: |

Sy synthesized in laboratory from natural material. Example, nylon 6, 6 , Buna-S |

|

Addition Polymers |

Formed by repeated addition of monomers

having multiple bonds . |

|

H Homopolymers. |

Aa Addition polymers formed from single monomeric species |

|

Copolymers |

A Addition polymers

formed from two different monomeric species |

|

C Condensation polymers |

F Formed by repeated

condensation of different bi or

tri-functional monomer units. |

|

F Fibers |

L Long thin, threadlike

bits of material that are characterized by great tensile (pulling) strength

in the direction of the fibre. The natural fibres – cotton, wool, silk

– are typical. The lining-up is

brought about by drawing – stretching — the return to random looping and

coiling is overcome by strong intermolecular attractions. |

|

E Elastomers |

P Possesses the high

degree of elasticity that is characteristic of rubber: it can be greatly

deformed — stretched to eight times its original length e.g., Buna N and Buna

S, When the stretching

force is removed, the molecular chains of an elastomer do not remain extended

and aligned but return to their original random conformations |

|

T Thermoplastic polymers |

S Soften on heating and

stiffen on Cooling. e.g.

polythene, polystyrene, PVC |

|

Thermosetting polymers |

Do not soften on

heating and cannot be remoulded. Example, Bakelite |