Methods of Polymerisation

There are two broad types of polymerisation reactions,

i.e., the addition or chain growth polymerisation and condensation or step

growth polymerisation.

Addition

Polymerization

Ø In this type of polymerisation,

the molecules of the same monomer or different monomers add together on a large

scale to form a polymer.

Ø The monomers used are

unsaturated compounds, e.g., alkenes, alkadienes

and their derivatives.

Ø This mode of

polymerisation leading to an increase in chain length or chain growth can take

place through the formation of either free radicals or ionic species.

Ø However, the free

radical governed addition or chain growth polymerisation is the most common

mode.

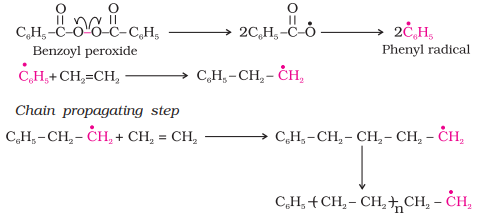

Free

Radical Mechanism

Ø A variety of alkenes or dienes and their derivatives are polymerised in the

presence of a free radical generating initiator (catalyst) like benzoyl

peroxide, acetyl peroxide, tert-butyl peroxide, etc.

Ø The process starts with

the addition of phenyl free radical formed by the peroxide to the ethene double bond thus generating a new and larger free

radical.

Ø This step is called

chain initiating step.

Ø As this radical reacts

with another molecule of ethene, another bigger sized

radical is formed.

Ø The repetition of this

sequence with new and bigger radicals carries the reaction forward and the step

is termed as chain propagating step.

Ø Ultimately, at some

stage the product radical thus formed reacts with another radical to form the

polymerised product.

Ø This step is called the

chain terminating step.

The sequence of steps may be

depicted as follows:

Chain

initiation steps

Chain

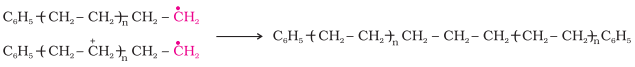

terminating step

For termination of the long chain, these free radicals

can combine in different ways to form polythene. One mode of termination of chain

is shown as under:

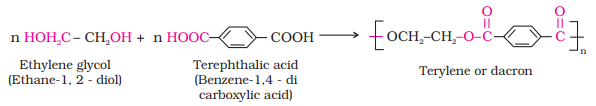

Condensation

Polymerization

Ø This type of

polymerisation generally involves a repetitive condensation reaction between

two bi-functional monomers.

Ø These polycondensation reactions may result in the loss of some simple

molecules as water, alcohol, etc., and lead to the formation of high molecular

mass condensation polymers.

Ø In these reactions, the

product of each step is again a bi-functional species and the sequence of

condensation goes on.

Ø Since, each step produces

a distinct functionalised species and is independent of each other; this

process is also called as step growth polymerisation.

Ø The formation of terylene or dacron

by the interaction of ethylene glycol and terephthalic

acid is an example of this type of polymerisation.

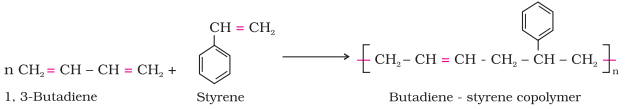

Copolymerisation

Ø Copolymerisation is a

polymerisation reaction in which a mixture of more than one monomeric species

is allowed to polymerise and form a copolymer.

Ø The copolymer can be

made not only by chain growth polymerisation but by step growth polymerisation

also.

Ø It contains multiple

units of each monomer used in the same polymeric chain.

Ø For example, a mixture

of 1, 3 – butadiene and styrene can form a copolymer.

Ø

Copolymers have properties quite different from homopolymers.

Ø

For example, butadiene - styrene copolymer is quite

tough and is a good substitute for natural rubber.

Ø

It is used for the manufacture of autotyres,

floortiles, footwear components, cable insulation,

etc.