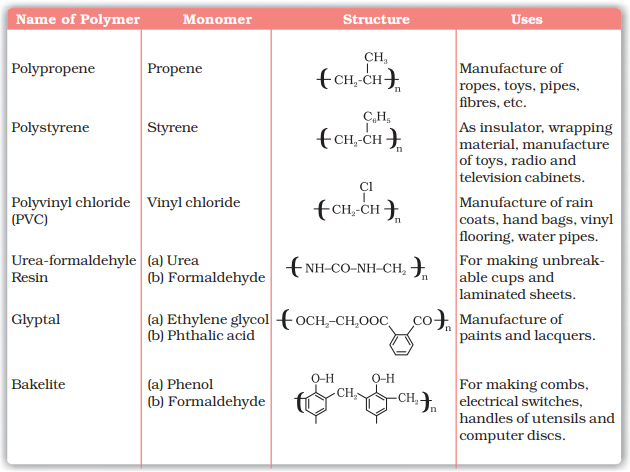

Some Important Polymers

Non – Biodegradable Polymers

1. Polythene

There

are two types of polythene as given below:

i.

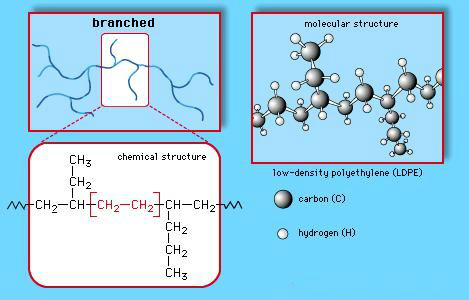

Low density polythene:

·

It is obtained by the polymerisation of ethene under high pressure of 1000 to 2000 atmospheres at a

temperature of 350 K to 570 K in the presence of traces of dioxygen

or a peroxide initiator (catalyst).

·

The low density polythene (LDP) obtained through the

free radical addition and H-atom abstraction has highly branched structure.

·

Low density polythene is chemically inert and tough

but flexible and a poor conductor of electricity.

·

Hence, it is used in the insulation of electricity

carrying wires and manufacture of squeeze bottles, toys and flexible pipes.

Low

Density Polyethene (LDPE) structures

ii.

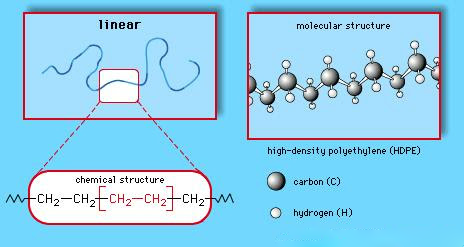

High density polythene:

·

It is formed when addition polymerisation of ethene takes place in a hydrocarbon solvent in the presence

of a catalyst such as triethylaluminium and titanium

tetrachloride (Ziegler-Natta catalyst) at a temperature of 333 K to 343 K and

under a pressure of 6-7 atmospheres.

·

High density polythene (HDP) thus produced, consists

of linear molecules and has a high density due to close packing.

·

It is also chemically inert and more tough and hard.

It is used for manufacturing buckets, dustbins, bottles, pipes, etc.

High

Density Polyethene (HDPE) structures

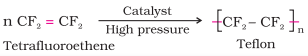

2. Polytetrafluoroethene (Teflon)

·

Teflon is manufactured by heating tetrafluoroethene

with a free radical or persulphate catalyst at high

pressures.

·

It is chemically inert and resistant to attack by

corrosive reagents.

·

It is used in making oil seals and gaskets and also

used for non – stick surface coated utensils.

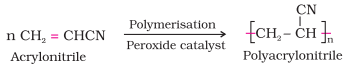

3. Polyacrylonitrile

·

The addition polymerisation of acrylonitrile in

presence of a peroxide catalyst leads to the formation of polyacrylonitrile.

·

Polyacrylonitrile is used as a substitute

for wool in making commercial fibres as orlon

or acrilan.

·

Acrylic fibres have good resistance to stains,

chemicals, insects and fungi.

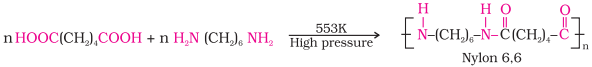

4. Polyamides

·

These polymers possessing amide linkages are important

examples of synthetic fibres and are termed as nylons.

·

The general method of preparation consists of the

condensation polymerisation of diamines with dicarboxylic acids and also of amino acids and their

lactams.

Preparation of nylons

i.

Nylon 16,6:

·

It is prepared by the condensation polymerisation of hexamethylenediamine with adipic

acid under high pressure and at high temperature.

·

Nylon 6, 6 is used in making sheets, bristles for

brushes and in textile industry.

ii.

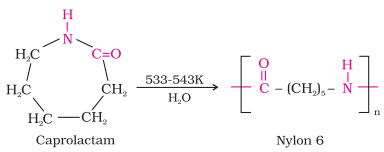

Nylon 6:

·

It is obtained by heating caprolactum

with water at a high temperature.

·

Nylon 6 is used for the manufacture of tyre cords,

fabrics and ropes.

5. Polyesters

·

These are the polycondensation

products of dicarboxylic acids and diols.

·

Dacron or terylene

is the best known example of polyesters.

·

It is manufactured by heating a mixture of ethylene

glycol and terephthalic acid at 420 to 460 K in the

presence of zinc acetateantimony trioxide catalyst as

per the reaction given earlier.

·

Dacron fibre (terylene)

is crease resistant and is used in blending with cotton and wool fibres and

also as glass reinforcing materials in safety helmets, etc.

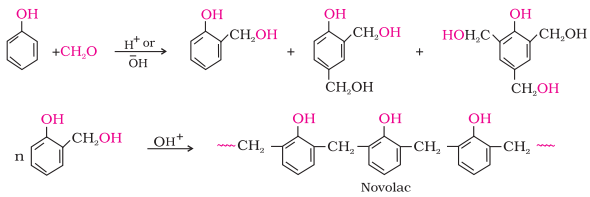

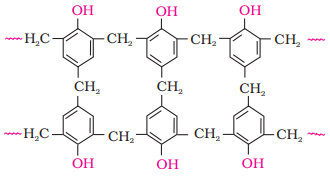

6. Phenol - formaldehyde polymer

(Bakelite and related polymers)

·

Phenol - formaldehyde polymers are the oldest

synthetic polymers.

·

These are obtained by the condensation reaction of

phenol with formaldehyde in the presence of either an acid or a base catalyst.

·

The reaction starts with the initial formation of o-and/or

p-hydroxymethylphenol derivatives, which

further react with phenol to form compounds having rings joined to each other

through –CH2 groups.

·

The initial product could be a linear product – Novolac used in paints.

·

Novolac on heating with

formaldehyde undergoes cross linking to form infusible solid mass called bakelite.

·

It is used for making combs, phonograph records,

electrical switches and handles of various utensils.

Bakelite

structure

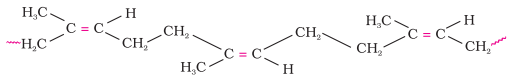

7. Rubber:

Natural rubber:

·

Rubber

is a natural polymer and possesses elastic properties. It is also termed as

elastomer and has a variety of uses.

·

It is

manufactured from rubber latex which is a colloidal dispersion of rubber in

water.

·

This

latex is obtained from the bark of rubber tree and is found in India, Srilanka, Indonesia, Malaysia and South America.

·

Natural

rubber may be considered as a linear polymer of isoprene (2-methyl-1,

3-butadiene) and is also called as cis - 1, 4 - polyisoprene.

·

The cis-polyisoprene

molecule consists of various chains held together by weak van der Waals

interactions and has a coiled structure. Thus, it can be stretched like a

spring and exhibits elastic properties.

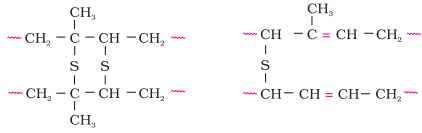

Vulcanisation of rubber:

·

Natural

rubber becomes soft at high temperature (>335 K) and brittle at low

temperatures (<283 K) and shows high water absorption capacity.

·

It is

soluble in non-polar solvents and is non-resistant to attack by oxidising

agents.

·

To

improve upon these physical properties, a process of vulcanisation is carried

out.

·

This

process consists of heating a mixture of raw rubber with sulphur and an

appropriate additive at a temperature range between 373 K to

415 K.

·

On

vulcanisation, sulphur forms cross links at the reactive sites of double bonds

and thus the rubber gets stiffened.

·

In the

manufacture of tyre rubber, 5% of sulphur is used as acrosslinking

agent.

Synthetic rubbers

·

Synthetic

rubber is any vulcanisable rubber like polymer, which

is capable of getting stretched to twice its length.

·

However,

it returns to its original shape and size as soon as the external stretching

force is released.

·

Thus,

synthetic rubbers are either homopolymers of 1, 3 -

butadiene derivatives or copolymers of 1, 3 - butadiene or its derivatives with

another unsaturated monomer.

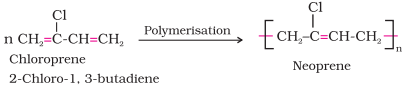

Preparation of Synthetic Rubbers

1.

Neoprene

·

Neoprene

or polychloroprene is formed by the free radical

polymerisation of chloroprene.

·

It has

superior resistance to vegetable and mineral oils. It is used for manufacturing

conveyor belts, gaskets and hoses.

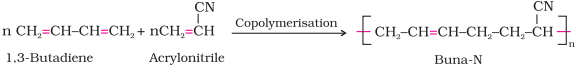

2. Buna – N

·

Buna –N

is obtained by the copolymerisation of 1, 3 – butadiene and acrylonitrile in

the presence of a peroxide catalyst.

·

It is resistant to the action of petrol, lubricating

oil and organic solvents. It is used in making oil seals, tank lining, etc.

Biodegradable Polymers

·

A large number of polymers are quite resistant to the

environmental degradation processes and are thus responsible for the

accumulation of polymeric solid waste materials.

·

These solid wastes cause acute environmental problems

and remain undegraded for quite a long time.

·

In view of the general awareness and concern for the

problems created by the polymeric solid wastes, certain new biodegradable

synthetic polymers have been designed and developed.

·

These polymers contain functional groups similar to

the functional groups present in biopolymers.

·

Aliphatic polyesters are one of the important classes

of biodegradable polymers.

Some important examples are:

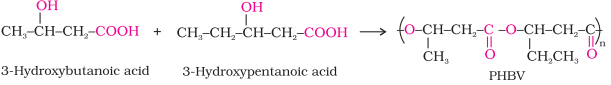

Poly ꞵ-hydroxybutyrate

– co-ꞵ-hydroxy

valerate (PHBV)

·

It is obtained by the copolymerisation of

3-hydroxybutanoic acid and 3 - hydroxypentanoic acid.

·

PHBV is used in speciality packaging, orthopaedic

devices and in controlled release of drugs.

·

PHBV undergoes bacterial degradation in the

environment.

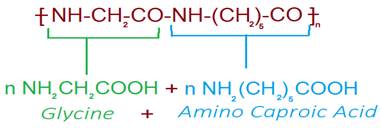

Nylon 2–nylon 6

·

It is an alternating polyamide copolymer of glycine

(H2N–CH2–COOH) and amino caproic acid [H2N(CH2)5COOH]

·

It is biodegradable.

Some Other Commercially

Important Polymers