Corrosion

Slow formation of undesirable compounds such as oxides, sulphides or

carbonates at the surface of metals by reaction with moisture and other

atmospheric gases is known as corrosion.

Factors affecting corrosion

i.

Reactivity

of metals.

ii.

Presence

of moisture and atmospheric gases like CO2, SO2, etc.

iii.

Presence

of impurities.

iv.

Presence

of electrolyte.

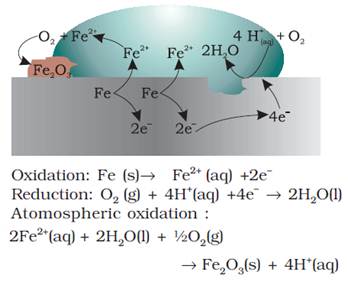

Electrochemical theory of rusting of iron

An electrochemical cell, also known as corrosion cell, is developed at

the surface of iron.

At a particular

spot of an object made of iron, oxidation takes place and that spot behaves as

anode.

Anode - Pure iron

Anode

reaction: 2Fe(s) →

2 Fe2+ + 4e– , ![]() = –

0.44 V

= –

0.44 V

Electrons released at anodic spot move through the metal and go to

another spot on the metal and reduce oxygen in presence of H+.

H+ is believed to be available from H2CO3 formed

due to dissolution of carbon dioxide from air into water. Hydrogen ion in water

may also be available due to dissolution of other acidic oxides from the

atmosphere.

This spot

behaves as cathode.

Cathode - Impure iron surface

Cathode

reaction: O2(g) + 4H+(aq)

+ 4e– → 2H2O(l), ![]() =

1.23V

=

1.23V

The

overall reaction:

2Fe(s) + O2(g) + 4H+(aq)

→ 2Fe2+(aq) + 2H2O(l), Eocell =1.67 V

Prevention of

rusting of iron:

Rusting

of iron can be prevented by the following methods:

1.

Barrier

protection through coating of paints or electroplating.

2.

Through

galvanisation or coating of surface with tin metal.

3.

By the

use of antirust solutions (bis phenol).

4.

By cathodic protection in which a metal is protected from

corrosion by connecting it to another metal that is more easily oxidised.